Leader in diversity

From an FT survey of European employees of corporates, AVEVA emerged as a leader in diversity.

Ethnicity pay gap

AVEVA’s work on our ethnicity pay gap reporting won us a 2021 Transparency Award at the Global Equality and Diversity Awards.

Best Companies for Women in India

After a rigorous and lengthy analytics process, India’s leading DEI consultancy has put AVEVA on its prestigious list of top employers for women.

“We’ve formally recognized the importance of a diverse and inclusive culture, and clearly defined it as one of AVEVA’s core principles. Executive sponsorship and sharing progress updates with all colleagues has reinforced the idea that inclusion is everyone’s responsibility.”

Steve Lewarne, VP Sales, Channel & Programs in the U.S.

Belonging

Grassroots employee groups within AVEVA amplify conventionally underrepresented voices and encourage us all to act as allies.

Wellbeing

With a structured combination of corporate and employee-led initiatives, wellbeing is ingrained in our culture.

Community

Our Action for Good program gives employees three days of paid volunteering leave every year.

Gender and ethnicity pay gap report

We are one of the few headquartered UK companies to report on both our gender and ethnicity pay gaps. We’re also part of the campaign to get more companies to follow us.

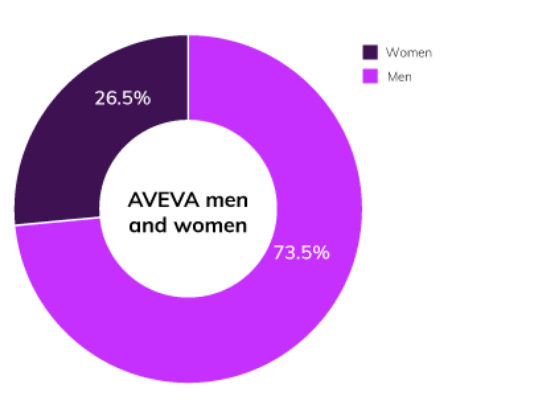

Global gender divide among employees

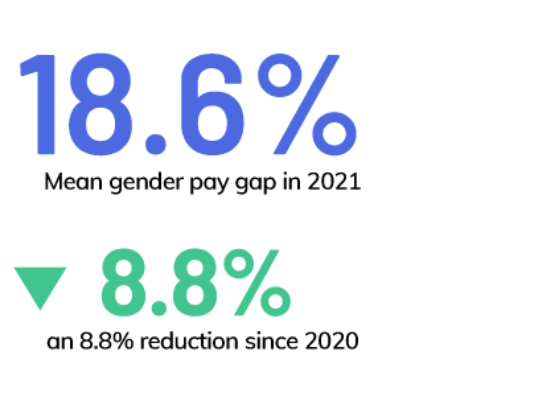

Global gender pay gap

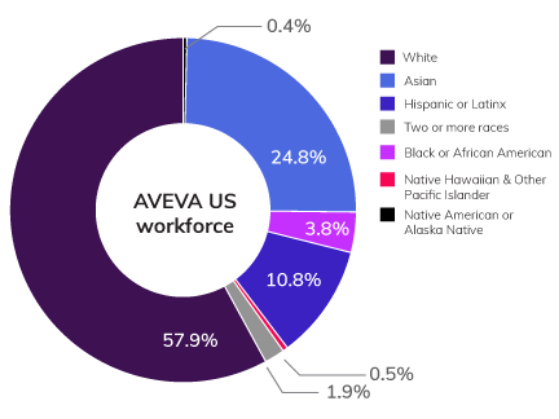

US workforce ethnicity breakdown

Empowering our employees

Training

Mandatory DEI training for all employees

Mental health

Access to colleagues

trained in mental health first aid available to all employees

Groups

Eight global employee groups

Regional networks

Continued investment

in the development of

our employee group

The path ahead

We understand that wellbeing is enhanced when people feel valued, respected, and that they belong. Our vision is that everyone who comes into contact with AVEVA feels that way, and that how we do business demonstrates our commitment to diversity, equity, inclusion, and wellbeing. Our five-year plan comprises five main objectives:

- Fostering inclusion

- Developing leadership capabilities

- Measuring performance and impact, and ensuring legal compliance

- Improving our diversity demographics

- Making our internal and external communications more effective

Our DEIW focus areas

Our 2030 gender targets

50%

Women new hires

40%

Women managers

30%

Women in leadership

“AVEVA’s aspiration for gender targets by 2030 is inspiring. I’m already seeing colleagues across departments come together as we endeavor to put our beliefs into action. I feel honored that I have this opportunity to make a difference in a small way to make our organization more inclusive and diverse.”

Kavitha Bhat, R&D Senior Manager and Women@AVEVA lead

Documents