Why manufacturers need to think about the three types of variety

Posted: August 19th, 2020

Multi-site standards are critical to digitally transforming a diverse manufacturing landscape at speed and scale.

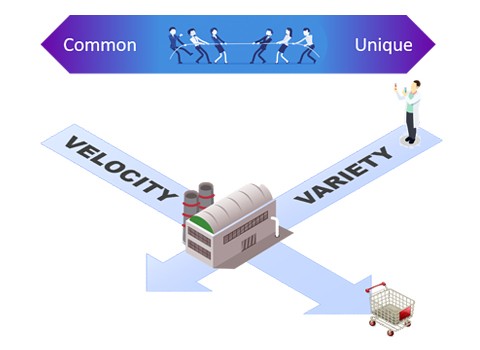

The fact that no two plants are identical isn't necessarily by design. The diversity across the manufacturing landscape is a result of accommodating unique attributes starting with site and project considerations in the build stage and continued adaptation to changing business conditions in the operations phase. Hence, digital transformation of manufacturing starts with establishing standard processes and practices. Having said that, standardization initiatives must also recognize that there are compelling business reasons for being non-standard. Finding the right balance is key because the tension between "common vs. unique" often manifests as opposing forces of "velocity vs. variety" in the supply chain.

In fact, the roots of this fundamental conflict between velocity and variety can be traced back to the origins of value chains.

About 100 years ago, Henry Ford famously said, "The customer can have any color they want as long as it is black." It wasn't that Ford didn't care about customer preferences. He said it because Ford (with the help of his chief industrial engineer, Frederick Taylor) was setting up the first mass production line of the 20th century and realized that variety was an opposing force to velocity.

Ford's River Rouge facility was more than just a production line - it hosted a full vertically-integrated value chain with 16 million square feet of factory floor space within 93 buildings connected by 100 miles of interior rail-road track that began with iron ingots and ended with a Model-T vehicle. The total cycle time from start to finish was 36 hours, which was a remarkable feat of supply chain velocity - back in 1928! The entire complex was a testament to Ford's vision and Taylor's ingenuity - but was designed to make just one product, quickly and efficiently.

Fast forward a hundred years since, velocity still rules. But variety is now equally important.

Speed is still the fundamental driving principle of supply chain management. It laid the foundation for the rise of modern-day successes like Dell, Walmart, FedEx, Amazon, etc. But for consumer-driven business models, success requires balancing velocity with another force that is important to growth - variety. For these businesses, increasingly, the message to the customer is "you are a unique individual with unique needs" where variety is central to the business strategy. And ground zero where these two opposing forces of velocity and variety meet is in manufacturing (in the form of changeovers.)

So how do we find the right balance between common vs. unique?

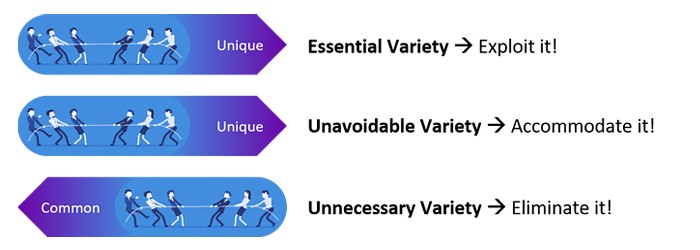

Companies starting their multi-site digital transformation journey need to keep in mind that standardization by itself is not a business goal. Rather, the goal of business is to make money by encouraging common as well as uniqueness - when appropriate. Thus, taking a pragmatic approach to standardization requires that we need to tackle the larger challenge of variety (or variability) by thinking of it in the 3 forms that exist within the business structure and the right approach to it:

The need to think bigger than standardization by understanding the three types of variety was the first topic of our Manufacturing 4.0 discussion series, which you can watch in the video below:

Related Blog Posts

Stay in the know: Keep up to date on the latest happenings around the industr