CONNECT: Where industrial intelligence meets operational excellence

How can CONNECT help you?

Lack of visibility across your value chain?

Gain real-time, unified insights from a secure, open and neutral platform connecting your entire enterprise and giving you a single view of operations across the entire value chain.

Siloed data and teams struggling to align?

By integrating IT, OT, and ET systems, CONNECT gives your team real-time access to critical information, so you can, make smarter and faster decisions that improve efficiency and drive business transformation.

Disjointed information inhibiting efficiency and growth?

Accelerate your transformation with powerful intelligence and robust insights. By optimizing processes, reducing costs, and improving resource efficiency, you can achieve operational excellence while driving sustainability goals.

SUCCESS STORIES

The CONNECT Effect in action

- AGL Energy

- VIVIX

- Centerra Gold

- YINSON

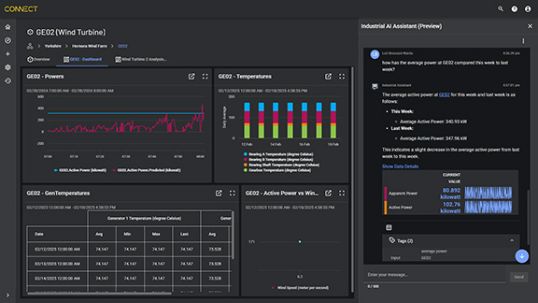

AGL Energy is an integrated energy company that produces energy from thermal power, gas, wind power, hydroelectricity, gas storage, and battery storage across Australia.

Since 2010, AGL’s supply capacity has grown from 300 megawatts of electricity generation to over 10,000 megawatts. As a result, the company has seen overwhelming growth in its data.

Using AVEVA software, AGL centralized its time-series information from every generation site. Now, the whole team has secure access to near-real-time data, and everyone is empowered to make changes that can improve many aspects of business performance.

“Our partnership with AVEVA has yielded significant operational value in data management, facilitating the delivery of operational insights and enhancing plant performance. The data is readily accessible, user-friendly, and available in real-time when necessary, empowering our sites to make informed operational decisions."

Goals

- To give teams across the organization access to real-time data and insights to improve accuracy of decision-making

- Expand from real-time awareness to predictive modelling to prevent lost time incidents.

- Share power generation data securely with partners, optimizing usage across distributed power generation sites.

Challenges

- Rapid energy transition drivers presented challenges managing data systems

- The team needed high-resolution data to optimize operational performance, especially with aging infrastructure

- The team had to consolidate scattered and isolated data, with multiple SCADA technologies in play, all within one system. They were able to achieve this with CONNECT

The CONNECT Effect

- Saved millions in avoided failures and maintenance costs

- Reduce data capture time from 10 mins to 1 sec across 200 wind turbines, helping optimize performance improvements and justify site-wide turbine upgrade

- Benefited from positive ROI and payback, and enhanced efficiency performance as a result

- Real-time wind power generation data from turbines is shared securely with 3rd parties to further optimize performance

Solution

VIVIX Glass adopted the combination of the CONNECT platform and AVEVA software to digitize a 3D model of its entire plant, connect that model to document and maintenance systems, and make all of the data available online in the cloud.

“Today we are in a completely different scenario, planning and executing our expansion project with collaborative, cloud-based tools that allow greater technical and budgetary efficiency.”

Goals

- Build a 3D digital twin of its cutting-edge float glass plant

- Connect the 3D model to VIVIX’s document and maintenance systems

- Make transfer of data more secure and efficient and give Vivix greater control over its own data

Challenges

- No as-built design of the plant existed and none of the documentation was 3D

- Dependent on an outside engineering partner to keep track of engineering data, including records of post-construction improvements

- External hard drives and courier services were used to transfer data between the plant and VIVIX’s engineering partner

The CONNECT Effect

- Reduced engineering project costs by 15%

- Cut travel expenses by 50% and use of IT team by 80%

- Reduced engineering CAPEX by making local servers unnecessary

- Real-time access to information enables reduction in inconsistencies

- Enabled VIVIX to build a subsequent plant more efficiently and sustainably and with a more robust engineering infrastructure

Solution

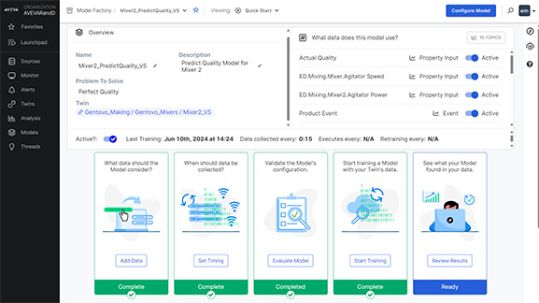

Centerra Gold is a Canadian-based gold mining company focused on exploring, developing, acquiring, and operating gold and copper at sites in North America, Turkey, and worldwide.

Centerra’s team faced issues with the accessibility and quality of OT data across its diverse site-based monitoring and control systems. They needed a secure, scalable solution that could integrate and transfer data to enable more accurate enterprise reporting and better decision-making.

“We got [the AVEVA team] involved and they suggested CONNECT data services. Everyone moved fast and we were able to get a solution in place in 2 weeks to meet our Go Live deadline.."

Goals

- Needed a quick, secure, and easy to implement solution to integrate data from AVEVA™ PI System™ into ERP system for enterprise reporting.

- Needed to deploy the solution in < 2 weeks to meet a tight deadline.

- Needed a trusted, secure, and scalable data-sharing platform, requiring limited IT involvement.

Challenges

- OT data in each mine siloed and opportunities missed to drive improvements in productivity, safety, and cost

- Process for data capture and collection is inefficient & error prone which resulted in poor data quality

- Inability to provide the right data to the right people, at the right time, to support decision-making

The CONNECT Effect

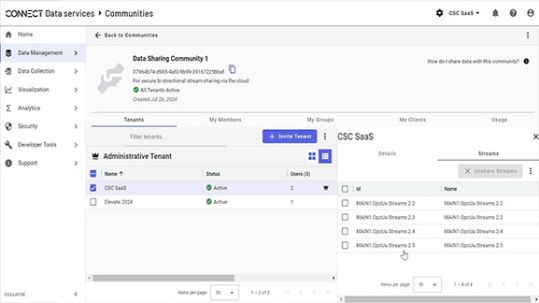

- OT data from site-based on-premises systems now integrated with CONNECT data services

- Seamless integration of AVEVA™ PI System™ with SAP (ERP) maintenance planning and business systems.

- Secure, reliable, timely and controlled access for third parties to Centerra’s IT/OT data.

- More efficient, and more accurate corporate reporting of production and compliance

Solution

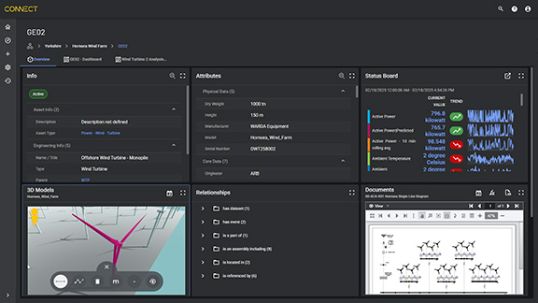

Yinson enhanced its data management and operational efficiency by integrating AVEVA™ PI System™ with AVEVA™ Engineering, supporting its growth and advancing towards net-zero emissions by 2050.

“By implementing AVEVA PI System, we were actually able to collect real-time data from the assets in operation."

Goals

- Streamline complex vessel design

- Structure and analyze data to enable analysis and optimization

- Reduce greenhouse gas emissions by 30% by 2030

Challenges

- Growing number and size of assets across the globe made it difficult to control data

- Duration and multidisciplinary nature of projects hampered data sharing and collaboration

- Capturing greenhouse gas emissions across operations to calculate baseline for future reductions

The CONNECT Effect

- Increased real-time data enables more efficient maintenance

- Data integration empowers increased collaboration across teams

- Moved from monthly calculations of greenhouse gas emissions to daily monitoring

Solution

In the news and thought leadership

Stay in the know: Keep up-to-date on the success of CONNECT.

Industrial transformation starts with CONNECT

Access trusted intelligence and gain valuable insights to empower your industrial ecosystem.

- Leverage rich, contextualized data through a unified and connected hybrid cloud experience built for your industry

- Streamline execution with real-time intelligence

- Stay ahead of the curve with enterprise visualization

- Collaborate across groups, break down silos and empower remote teams

- Optimize efficiency, cut costs, and reduce waste