Ence is three businesses in one: A forest manager in the Iberian Peninsula, Europe’s largest producer of eucalyptus pulp products, and Spain’s leading biomass power operator. All together, these three arms of the enterprise form Ence’s own sustainable, circular economy. To push its sustainability ambitions even further, Ence created an internal team with one purpose: to develop new data-driven tools from its existing AVEVA investment. By making better use of the AVEVA PI System portfolio, like AVEVA PI Server’s event frames, notifications, and asset framework, the team launched multiple pilot programs that reduced downtime, process variability, and emissions across its three business sectors.

Challenges

Process variability hampered energy efficiency

Water shortages led to operational downtime

A reactive approach to maintenance was failing to keep pace with increasingly frequent environmental deviations

Results

15%

Reduction in emissions and 1,500 MWh saved in each pulp mill

Reduced summer downtime due to water shortage from 15 days to zero the following year

Improved ability to anticipate and plan for environmental deviations

€150,000

Saved per year in biomass consumption

10%

Reduction in emissions at the biomass power plant

The next step in sustainability

Within Ence Energía & Celulosa, there are actually three distinct, but deeply interconnected businesses, which together form Ence’s own circular economy. In one part, Ence is a forest manager, owning over 65,000 hectares of eucalyptus forest in the Iberian Peninsula. These forests provide Ence with the raw materials for its other two businesses as Europe’s leading producer of eucalyptus pulp products, and Spain’s leading biomass operator, turning agricultural and forestry waste into renewable energy. The company operates eight biomass power plants, as well as its two pulp mills.

At the heart of each of these three businesses lies Ence’s commitment to sustainability, for which the organization has won numerous awards, certifications, and other recognitions. To push its sustainability goals even further, all while reducing downtime and process variability, Ence turned to AVEVA.

Unlocking value from existing data

Ence’s relationship with AVEVA dates back to 2015 when it installed AVEVA PI System portfolio. By the early 2020s, however, Ence was generating more data than ever, all of which needed to be organized and managed effectively before it could be turned into real-world value. After numerous workshops and considerable internal research, the team at Ence came to a realization. “At our fingertips, we had a great potential that was yet to be fully exploited,” says Iago Rodriguez Fernandez, Digitization Technician at Ence.

The team saw that there were tools and capabilities under the AVEVA PI System umbrella they hadn’t fully leveraged, like AVEVA PI Server's event frames, notifications, and the asset framework feature, which allows engineers, operators, or even non-technical staff to quickly find the information they need, analyze trends, and make smarter decisions.

Ence created an internal team to develop new tools built on AVEVA solutions. Over the next two years, the team built up its competence in the software, launching and scaling pilot programs across the three sectors of its business. As their confidence in their AVEVA toolkit grew, they adopted more AVEVA solutions, including CONNECT and EcoStruxure APC.

“We realized that at our fingertips we had a great potential that was yet to be fully exploited.”

-- Iago Rodriguez Fernandez, Digitization Technician, Ence

Solution

Deployed AVEVA™ PI System™, AVEVA™ PI Vision™, CONNECT, and EcoStruxure Advanced Process Control to streamline data management, extend its value, and optimize energy efficiency.

Ence’s new control loop monitoring and diagnostics solution empowers engineers in the pulp mills with precise instrumentation control, status overviews, and issue detection, and analysis.

Ence’s new control loop monitoring and diagnostics solution empowers engineers in the pulp mills with precise instrumentation control, status overviews, and issue detection, and analysis.

Improving pulp mill operations

Among these early pilot programs was Ence’s optimization of the control loops across its pulp mill facilities.

Ence combined the asset framework and event frame features of AVEVA PI Server with AVEVA PI Vision—the flagship visualization tool for the AVEVA PI System portfolio—to develop its own control loop monitoring and diagnostic solution. The solution empowers Ence with precise control of its instrumentation to ensure critical processes remain within optimal ranges for optimal process efficiency.

The solution provides Ence with a general overview of all the control loops in its facilities; it enables early issue detection, as well as deviation analysis and diagnostics, so that the team can jump into action, perform proactive maintenance, and avoid unplanned downtime. Already, the new control loop solution has helped Ence reduce emissions by 15% and save 1,500 MWs per hour per year in each pulp mill.

Reducing water consumption and unplanned downtime

Water is essential across the stages of pulp mill operations. And while water was once abundant in the north of the Iberian Peninsula, increasingly frequent and severe droughts have made it a much more precious resource. "Accurate control of our water consumption in each part of our pulp mill is essential to achieving our goals,” says Fernandez. To reduce its water consumption footprint while enhancing the resilience of its operations, again, Ence found the solution in its data.

With all its data from all the various corners of its facilities accessible in AVEVA PI System, and contextualized using asset framework, Ence can easily publish this data to CONNECT. The result is a comprehensive report of all Ence’s water usage data and trends, which gives the team greater control of its consumption to better meet the resource challenges of the moment. “At the slightest deviation,” Fernandez says, “we are able to take action quickly.” Ence saw 15 days of operational downtime in the summer of 2023 due to water limitations. In the first summer season with its new system in place, that figure dropped to zero.

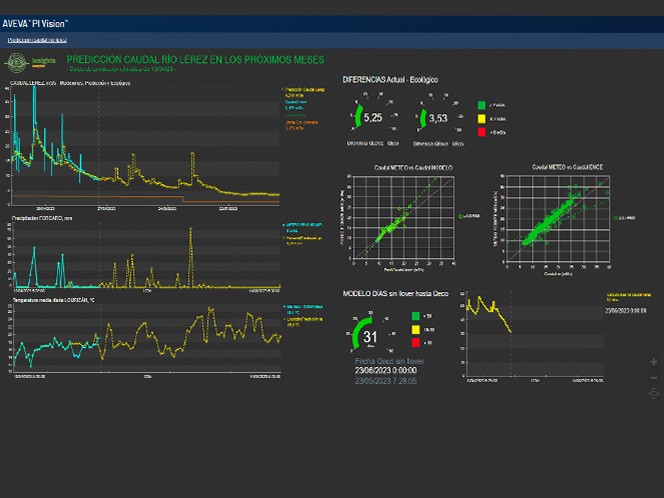

In the AVEVA PI Vision display above, the yellow line depicts the predicted river flow while blue indicates the actual river flow.

In the AVEVA PI Vision display above, the yellow line depicts the predicted river flow while blue indicates the actual river flow.

In the forest management sector of its business, Ence uses AVEVA PI System data to feed deep learning machine algorithms, which Ence uses to better plan and manage its water consumption. These algorithms integrate flow meter, historical rainfall data, as well as data from official weather stations to predict the flow of the river that feeds their pulp mill facility. Then, using AVEVA PI Vision, the team can visualize these predictions and plan accordingly.

Optimizing biomass power generation

As wind and solar power penetrate deeper into Spain’s energy mixture, the intermittent nature of these power sources is also introducing new instability into the power grid. To help mitigate this instability, Ence makes its biomass power plant available to the grid operator, which improves the operator’s ability to balance supply and demand in real time. For Ence’s power plant, however, this means continuous load changes, which impact the efficiency of the generation process. Ence wasn’t able to make up that loss in efficiency using its traditional approach to process control, so the team turned to EcoStruxure APC to close the gap.

Unlike control loops, which correlate an input and output variable, EcoStruxure APC creates multivariable models capable of predicting combustion behavior. These models can anticipate and adjust setpoints to maintain process stability before destabilization occurs, ensuring optimal process performance.

By automating control loops with EcoStruxure APC, Ence has saved time—avoiding nearly 900 manual interventions a day—and improved process efficiency and sustainability. Each year, Ence now saves about €150,000 in biomass consumption, and has reduced emissions by as much as 10%.

Sustainable growth, sustainable outcomes

As Ence continues to scale its programs using AVEVA technology, it expects to unlock even greater cost savings and sustainability gains across its operations. The early wins reinforce a powerful idea: sustainable practices and profitable growth don’t have to be competing objectives; they’re two sides of the same strategy.

Product highlights

AVEVA™ PI System™

Collect, aggregate, and enrich real-time operations data for immediate problem-solving and easily deliver formatted data to enterprise applications and advanced analytics.

CONNECT

Our industrial intelligence platform: securely access the broadest and deepest industrial software-as-a-service (SaaS) portfolio enhanced by the power of industrial Artificial Intelligence (AI).

AVEVA PI Vision

With AVEVA PI Vision, turn raw data into rich, visual displays and share valuable insights across your enterprise.