Ormat is a global leader in the renewable energy sector, recognized as the number one company in geothermal power. It is committed to innovation that advances the efficiency of technologies for renewable energy development, reduces energy waste, and provides sustainable energy management solutions. Ormat’s primary goal is to be highly reliable and optimize the performance of its 24-hour geothermal power plants. In partnership with AVEVA Select Partner, Casne Engineering, Ormat accesses AVEVA™ Plant SCADA and AVEVA™ Historian, and has integrated the AVEVA™ PI System™ portfolio into its workflow. Now, Ormat is equipped with a robust data infrastructure that supports real-time monitoring, predictive maintenance, and performance optimization.

Challenges

Lacked optimal geothermal energy production

Time-consuming data access

Critical thermodynamics calculations done manually in Excel

Needed an integrated solution for data analytics and visualization

Results

$1 million

in added revenue per plant per year on average, driven by an additional 1–3.5 MW of power generation per plant

Unaccounted for cost savings in predictive maintenance

Developed an asset hierarchy, actionable dashboards, and a custom thermodynamics calculation solution to improve situational awareness and enable the real-time analysis of critical plant processes

Building a platform for asset reliability

Ormat is a leading company in the renewable energy sector, specifically recognized as the number one global company in geothermal power. It is committed to innovation in renewable energy development, reducing energy waste, and providing sustainable energy management solutions to its customers. With over 60 years of experience, it currently owns and operates over 1.5 gigawatts of renewable geothermal, storage, solar photovoltaic (PV), and recovered energy generation (REG) plants.

Ormat’s geothermal power plants use a closed-loop system for sustainable power generation. Hot brine is extracted from underground and its heat is transferred to a motive fluid in a vaporizer. The vaporized fluid drives a turbine, which generates electricity. Afterward, the motive vapor is condensed, reheated, and recirculated to maximize efficiency. The extracted brine, now cooled, preheats the motive liquid before being reinjected into the earth, ensuring all geothermal fluids are returned underground. This process maintains resource sustainability while delivering reliable, round-the-clock renewable energy, which exemplifies Ormat’s commitment to efficiency and environmental responsibility in geothermal energy production.

Ormat is the only company in the world with the capability to manage the entire lifecycle of geothermal activity. Its vertically integrated structure allows it to offer flexible business models and comprehensive turnkey solutions tailored to specific sites and conditions, which provides significant advantages to its clients.

“For this to operate properly, we must have a real-time system that monitors the asset performances at any time for each asset. So we can optimize our performance, reduce downtime, and improve availability and reliability.”

– Yehiel Viner, VP Technical and Maintenance, Ormat

Delivering reliability and performance

Ormat’s primary goal is to be highly reliable by optimizing the performance of its geothermal power plants, which operate 24 hours a day. The deceptively simple geothermal process has its own set of unique challenges: scaling, declining well performance, equipment vulnerability due to numerous moving parts, reservoir sustainability, and the critical task of ensuring continued injectivity without excessive back pressure.

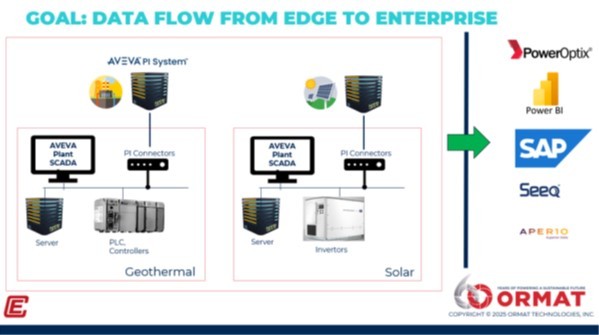

Goal: Data flow from edge to enterprise

Ormat worked with AVEVA Select Partner, Casne Engineering, to develop a smart analytics solution for equipment monitoring and control that would enhance the efficiency and reliability of its geothermal plants.

Central to Ormat’s data infrastructure is the AVEVA PI System portfolio. It collects real-time data from various sources, including production wells and plant equipment. AVEVA™ PI Server enables Ormat to build an Asset Framework (AF) infrastructure, which models the assets and their relationships. Building specific PI AF templates for each individual asset type allows Ormat to monitor the current status of each asset, ensure maximum capacity utilization, and identify issues for decision-making.

This templated approach has allowed it to rapidly scale its solutions across multiple sites, going from a few sites per year to 11 in a single quarter. This framework supports advanced analytics and visualization, allowing Ormat to monitor plant performance and optimize its operations.

“The bottom line is that in all renewables, every megawatt or kilowatt we are not generating is gone because there’s no way to get it back; there are no raw materials in this industry.”

– Yehiel Viner, VP Technical and Maintenance, Ormat

Ormat aims for trusted data flow from edge to enterprise

Ormat aims for trusted data flow from edge to enterprise

For data visualization, Ormat implemented AVEVA PI Vision. It now relies on AVEVA PI Vision’s multi-state behaviors to rapidly detect out-of-range values and quickly identify problems like tube leaks in vaporizers or failed cooling tower fans, based on their operational know-how. They also display key performance indicators (KPIs) for operators on dashboards in PI Vision, allowing for a quick identification of issues and potential generation improvements.

To streamline and enhance plant performance, Ormat has developed dashboards for equipment like condensers and cooling towers, which integrate real-time and simulated data for performance comparisons. Previously, analytics involved time-consuming manual processes in Excel. Now, using the AF SDK, which provides programmatic access to AVEVA PI Server’s asset framework, Ormat can automate complex calculations—such as thermodynamic modeling and goal seeking by pulling data from templates, running computations in a custom application, and writing results back. This standardizes analytics across all sites and enables rapid scaling: new plants simply instantiate new templates. Live, automated calculations empower users to detect inefficiencies and improve generation, which is a significant leap from manual methods.

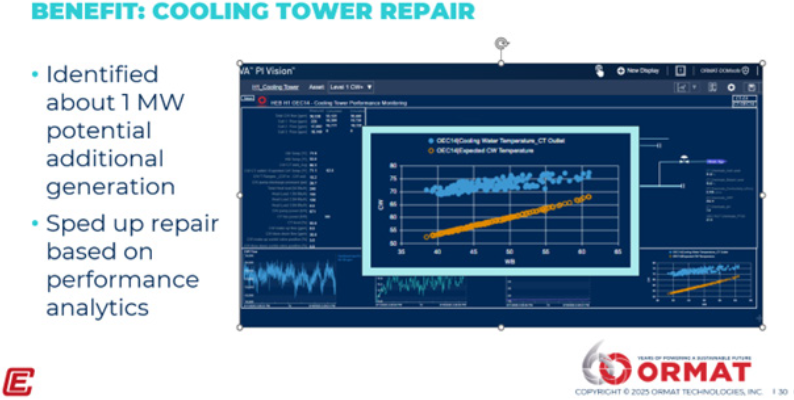

Ormat has also integrated simulation-based calculations into AVEVA PI System, which display digital twins of assets with actual versus expected performance in AVEVA PI Vision dashboards. With PI Interface for Relational Databases (RDBMS via ODBC), Ormat pulled in SQL data from its proprietary simulation tool. The configured solution enables Ormat to quickly identify underperforming equipment and determine if each plant is utilizing its maximum capacity efficiently.

At each geothermal and solar site, AVEVA Plant SCADA is used. This Supervisory Control and Data Acquisition (SCADA) solution provides real-time monitoring and control of Ormat’s renewable plants. It collects data from sensors and equipment, enabling operators to monitor the status of the plant and make informed decisions. The integration of AVEVA Plant SCADA with the AVEVA PI System ensures that data is consistently collected and analyzed.

While AVEVA PI System is now deployed across its geothermal sites, Ormat continues to rely on AVEVA Historian at its solar sites. This solution provides a comprehensive record of plant operations, which can be used for trend analysis, performance benchmarking, and regulatory compliance. AVEVA Historian also supports backfilling data into the AVEVA PI System, ensuring that historical data is available for analysis and decision-making at all levels of the business.

Solution

AVEVA PI System provides streamlined data collection, access, analysis, and visualization across its geothermal assets.

AVEVA PI Vision is used for data visualization, KPIs, and rapid detection of out-of-range values.

AVEVA Historian enables data collection and analysis of its solar assets.

AVEVA Plant SCADA manages and monitors various real-time industrial processes across both geothermal and solar assets.

AI-infused predictive analytics and virtual plant

These AVEVA solutions work together to provide Ormat with a robust data infrastructure that supports real-time monitoring, predictive maintenance, and performance optimization. By leveraging these technologies, Ormat has achieved substantial cost savings, improved operational efficiency, and increased generation capacity.

By embracing the principle of “Keep It Simple and Standard” (KISS), Ormat achieved remarkable improvements. The new system featuring AVEVA has enabled Ormat to extract an estimated extra megawatt per site, which translates to roughly one million dollars of added value per location. Scaling this across the entire fleet could save Ormat up to $30 million.

Ormat’s cooling tower repair analytics have identified about 1 MW of potential additional generation

Ormat’s cooling tower repair analytics have identified about 1 MW of potential additional generation

“It’s amazing. If we do it across all the plants it’s $30 million of saving that we can put into our bottom line. Of course, the system will not fix it, but it will identify what we should do. So, it’s not a pure saving, but it’s an identifying saving.”

– Yehiel Viner, VP Technical and Maintenance, Ormat

Product highlights

AVEVA™ PI System™

Collect, aggregate, and enrich real-time operations data for immediate problem-solving and easily deliver formatted data to enterprise applications and advanced analytics.

AVEVA PI Vision

With AVEVA PI Vision, turn raw data into rich, visual displays and share valuable insights across your enterprise.

AVEVA Historian, formerly Wonderware

Formerly Known As Historian

Empower people with high-fidelity historical data from operations, enabling them to solve problems faster, make better data-based decisions, and increase productivity.

AVEVA™ Plant SCADA

Formerly Known As Citect SCADA

AVEVA Plant SCADA (formerly Citect SCADA) is the leading flexible, high-performance supervisory control and data acquisition (SCADA) system for industrial-process and infrastructure customers.