Dragon LNG, one of the United Kingdom’s major liquefied natural gas terminals, faced a dilemma hiding in plain sight. The facility capable of sending out nearly 300 GWh of natural gas each day was running well within safe design parameters, but this conservative operation meant potential cost and energy savings were left untapped. In a context of fluctuating grid pressure and varying LNG cargo compositions, operators kept extra equipment online and maintained wide safety margins. While this ensured consistent output, it also led to higher energy use. With a goal to become a net-zero emissions facility by 2029, reducing unnecessary energy consumption became a pressing priority.

To address this, Dragon LNG partnered with AtkinsRéalis, a global engineering and infrastructure services company, for a new approach. AtkinsRéalis combined AVEVA™ Process Simulation, AVEVA™ PI System and , AVEVA™ PI Vision™ and deploying an industrial digital twin to optimize Dragon LNG’s end-to-end production, compression, and logistics network.

Challenges

Potential operating cost savings were available, but it was unclear how to obtain them

The original design and operator guidance were overly conservative

Large volumes of product required high confidence in quality of output

Results

$1M

energy savings identified

Confidence in results enables a savings-share commercial model

developed a new commercial offering to deploy a digital twin for real-time process optimization to other customer plants

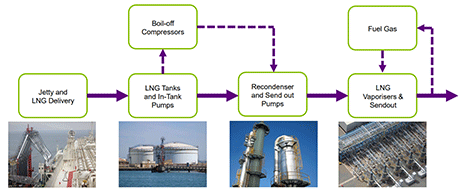

This illustration of a typical LNG terminal process represents the core operational systems that must be balanced and optimized to ensure efficient energy use and reliable gas delivery.

This illustration of a typical LNG terminal process represents the core operational systems that must be balanced and optimized to ensure efficient energy use and reliable gas delivery.

Dragon LNG, one of the United Kingdom’s major liquefied natural gas terminals, faced a dilemma hiding in plain sight. The facility capable of sending out nearly 300 GWh of natural gas each day was running well within safe design parameters, but this conservative operation meant potential cost and energy savings were left untapped. Operators followed original design guidelines that err on the side of caution, ensuring reliability and gas quality above all. In an environment where grid pressure fluctuates and each incoming LNG cargo had a slightly different chemical composition, the default practice was to keep extra equipment online and maintain generous safety margins. While this approach guaranteed output, it also meant higher energy use. Management suspected that significant efficiency gains were possible, but it was unclear how to realize them without risking the terminal’s performance. And with Dragon LNG’s ambition to become a net-zero emissions facility by 2029, finding a way to cut unnecessary energy consumption had become an urgent priority.

Finding a way to cut unnecessary energy consumption was a newly urgent priority. Dragon LNG turned to AtkinsRéalis for a fresh approach. AtkinsRéalis - a global engineering and infrastructure services company had been looking to transform how industrial sites optimize performance in real time. The team at AtkinsRéalis proposed a bold idea: use a live digital twin of the Dragon LNG facility to test and identify optimal operating configurations in real time. Rather than rely solely on conservative guidelines, Dragon LNG’s operators would get data-driven recommendations based on a continuously updated virtual model of its plant. This marked a turning point for Dragon LNG’s operations. By embracing AVEVA’s advanced process simulation and data visualization tools, the terminal would move from static, experience-based adjustments to dynamic, model-driven optimization.

AtkinsRéalis combined AVEVA Process Simulation with AVEVA PI System. It implemented a deployable digital twin for real-time, data-driven process optimization across the Dragon Liquified Natural Gas (LNG) terminal in Milford Haven, South Wales.

Solution

AtkinsRéalis used AVEVA Process Simulation, AVEVA PI Vision and AVEVA PI System to collect, contextualize, analyze, and visualize asset performance and operations data at Dragon LNG. This included deploying an industrial digital twin to optimize Dragon LNG’s end-to-end production, compression, and logistics network.

Real-time operational efficiency savings: an LNG case

The convergence of several solutions from AVEVA is enabling Dragon LNG and AtkinsRéalis to monitor and optimize the performance of an LNG terminal in Wales. Real-time data from AVEVA PI System flows seamlessly into AVEVA Process Simulation, where it is used to calculate a variety of performance metrics. The industrial digital twin offering is then used to optimize process setpoints and to enable greater energy efficiency for the terminal. And since AtkinsRéalis uses AVEVA Process Simulation for process design engineering, additional training and expertise are not needed.

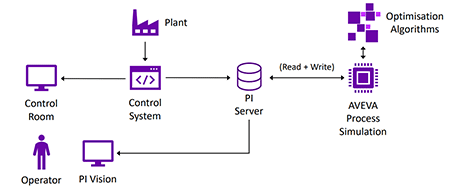

AtkinsRéalis deployed a system architecture that integrates AVEVA PI Server, AVEVA PI Vision, and AVEVA Process Simulation with its proprietary optimization algorithms to deliver real-time, actionable recommendations for Dragon LNG's operators.

AtkinsRéalis deployed a system architecture that integrates AVEVA PI Server, AVEVA PI Vision, and AVEVA Process Simulation with its proprietary optimization algorithms to deliver real-time, actionable recommendations for Dragon LNG's operators.

Thanks to this native integration, AtkinsRéalis has been able to concentrate on the real engineering challenges of how and when the plant can be optimized. Working closely with the site to ensure that the model is as accurate as possible, the solution has the potential to deliver significant savings by providing operators with immediate feedback on the best operating regime to implement. The same solution also provides health information about key plant items, enabling more responsive maintenance. The offering has been tested against multiple years of site operation to provide proof of its savings potential.

Powered by live and historical data from AVEVA PI Server and predictive modeling from AVEVA Process Simulation, this AVEVA PI Vision display enables operators to visualize energy usage, assess equipment health, and receive actionable recommendations for optimized plant operation.

Powered by live and historical data from AVEVA PI Server and predictive modeling from AVEVA Process Simulation, this AVEVA PI Vision display enables operators to visualize energy usage, assess equipment health, and receive actionable recommendations for optimized plant operation.

The challenge of optimization

Optimizing plant operations presents a unique challenge. While operations can be based on design capacity under ideal conditions, such as design send-out pressure and composition, real-world variables often differ -Grid pressure fluctuates, and each cargo brings a slightly different LNG composition.

To address uncertainties, a digital twin for real-time data was developed that compares the current plant set-up against multiple potential configurations and presents the results in an AVEVA PI Vision dashboard. It provides operators with recommendations for the most feasible and optimized configuration. The tool assesses five years of operational data and matches live plant output with over 97% accuracy. In addition, it supports the health monitoring of major equipment and control valves, enhancing both reliability and performance.

A blueprint for the future of LNG operations

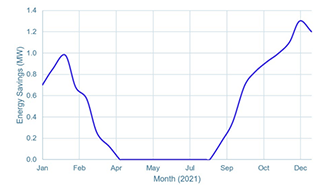

What started as a pilot at a single LNG terminal in South Wales is now becoming a blueprint for how modern gas facilities can run smarter. The collaboration between AtkinsRéalis and AVEVA has demonstrated a powerful point: Real-time digital twins can unlock efficiency improvements that were previously out of reach for complex industrial operations. Dragon LNG’s experience shows that even in a conservative industry like LNG processing, embracing data and simulation can yield both economic and environmental benefits. The energy savings—on the order of a million dollars per year—also translate into a substantial reduction in the terminal’s carbon footprint, directly supporting Dragon LNG’s journey toward net-zero emissions by 2029.

Significant potential savings

Significant potential savings

Over the course of a year, the plant can reduce energy usage by an average of 0.5 to 0.7 MW, translating to approximately $1 million in annual cost savings. These savings are particularly substantial during the winter months, when send-out rates are at their peak. Analysis showed that a more optimal plant configuration was available 60 to 80% of the time, highlighting consistent opportunities for efficiency improvements.

The collaboration between AtkinsRéalis and AVEVA has delivered a powerful and practical solution to one of the energy sector’s most pressing challenges: real-time optimization of complex operations. By integrating AVEVA Process Simulation with AVEVA PI System, AtkinsRéalis successfully deployed a digital twin for process optimization that not only enhances day-to-day operational decision-making at Dragon LNG but also supports long-term sustainability goals through significant energy and cost savings. With proven accuracy, tangible results, and seamless usability, this solution sets a new benchmark for digital transformation in LNG operations.

Conclusion

The Dragon LNG case illustrates that digital tools aren’t just for design or offline analysis; they can be woven into the fabric of real-time decision-making on the plant floor. Operators, empowered with clear visuals and trusted predictions, become more like pilots with advanced instruments—able to navigate their plant through changing conditions with confidence and agility.

Product highlights

AVEVA Process Simulation

Formerly Known As SimCentral Simulation Platform

Design sustainable processes, products, and plants at the speed the market demands. AVEVA Process Simulation moves beyond linear, wasteful workflows to enable a circular, sustainable world.

AVEVA PI Vision

With AVEVA PI Vision, turn raw data into rich, visual displays and share valuable insights across your enterprise.

AVEVA™ PI System™

Collect, aggregate, and enrich real-time operations data for immediate problem-solving and easily deliver formatted data to enterprise applications and advanced analytics.

Related success stories

Stay in the know: Keep up to date on the latest happenings around the industry.