LondonEnergy’s new waste management hub converts waste into power and heat for tens of thousands of homes in north London. But disparate systems, manual processes, and lack of visibility into equipment all posed challenges to site operations. So LondonEnergy created a centralized operations center to unite systems, streamline maintenance, and optimize processes. This allowed the company to reduce energy consumption by 20% across the site, with an estimated £150,000-200,000 in savings each year.

Challenges

Complex disparate systems and manual processes delayed critical decisions

Difficult to perform root cause analysis and reaction time took too long

Previous deployment with a SCADA system was unable to scale with site growth

Results

20%

reduction in energy consumption across the site, with an estimated £150,000-200,000 savings each year

13

minutes on average to automatically direct vehicles on and off site, against a target of 20

mitigated and controlled factors such as fires and odor with real-time monitoring of assets

automated and streamlined maintenance, cutting maintenance hours by at least half, as well as enabled remote monitoring

able to manage wastewater flows to consistently meet discharge parameters set by Thames Water

A centralized operations center

Waste from landfills and wastewater makes up about 20% of human-caused methane emissions. With populations growing and infrastructure aging, the problem is only expected to get worse. LondonEnergy, owned by the North London Waste Authority (NLWA), is working to mitigate the problem with new energy recycling and recovery facilities that improve waste processing and convert any residual product into power and heat for tens of thousands of homes in north London. “This major investment in north London will ensure that there is truly resilient and safe infrastructure to sustainably deal with the waste generated by two million residents in the long term,” says Clyde Loakes, NLWA Chair. “It means not shipping waste abroad or to a landfill where it will rot and generate methane. Instead, it means using waste to generate energy, which in turn boosts the UK’s security of energy supplies.”

But just as the physical infrastructure of the London EcoPark—built over fifty years ago—needed to be replaced, the technological infrastructure needed an overhaul. So LondonEnergy, in partnership with systems integrator March and distributor SolutionsPT, used AVEVA software to create a centralized operations center.

Waste management facility gets a facelift

EcoPark South is the first phase in NLWA’s plan to build a £1.2bn sustainable waste management hub at Edmonton EcoPark. It’s made up of three facilities: EcoPark House, an education and visitors’ center where people can learn about recycling sources, renewable energy, and how to reduce the carbon impact of their waste; the Reuse and Recycling Center (RRC), where the public can drop off their household waste; and the Recycling and Fuel Preparation Facility (RFPF), where LondonEnergy sorts waste for recyclables before preparing the rest for treatment at its Energy from Waste (EfW) power plant. The RFPF has the capacity to manage 135,000 tonnes of material every year, with over 200 waste truck transactions per day. This is waste saved from the landfill and reused as energy— reducing emissions and the need for fossil fuels while providing affordable heating and electricity.

LondonEnergy needed to modernize this facility to operate more efficiently and minimize the environmental impact of operations. The facility’s residential location meant that odor, wastewater treatment, dust, and frequent fires due to a rise in vaping and lithium batteries in today’s waste streams were all of primary concern. Additionally, LondonEnergy had to address these concerns and revamp operations with the same size staff as before. The manual processes and disparate systems the facility had relied on for fifty years were no longer viable.

"The [new] SCADA provides our management team with the ability to interrogate key data and trends to ensure we are efficiently managing the site. This includes the monitoring of energy usage, throughput/storage of waste and water, and usage of key systems (including fire systems).”

-- Ben Kelso, Transition Director, LondonEnergy

Connecting disparate systems in one data-centric environment

Historically, LondonEnergy had used a building management system (BMS) to manage facility data, but the scope and complexity of this new site called for a solution that went beyond a traditional BMS. So LondonEnergy, working with March—a systems integrator providing critical engineering services in infrastructure, process and digital environments—used AVEVATM System Platform to create a centralized operations center. Incorporating the necessary BMS capabilities into its SCADA system, LondonEnergy was able to bring the disparate systems of EcoPark South—over 50 subsystems—together and centralize visibility across key building management parameters such as HVAC alongside its critical operations data points.

This unique combination of BMS and SCADA in one unified operations hub means LondonEnergy can now make faster, more informed decisions across its facilities and reduce operational risks.

All three facilities are overseen 24/7 by a centralized operations team in the “crow’s nest” in the RFPF. Supervisors can monitor key systems and processes, including approximately 200 waste-tipping vehicles each day, roller-shutter doors, the integrated ventilation and odor system, wastewater treatment, surface water treatment, and gas and fire detection. The new system helps with automatically directing vehicles on and off site quickly, on average within 13 minutes, against a target of 20, saving considerable time across the plant. Additionally, they can monitor energy consumption, solar power distribution, and ensure the safety of people and plant—all in one centralized location.

This centralized visibility of real-time data enables proactive monitoring and faster responses to operational issues. Planned preventative maintenance for each system requires approximately 600 work orders for LondonEnergy’s four-person maintenance team per month. With its new data infrastructure, some of these checks can be done automatically, saving valuable maintenance hours per week. Additionally, the system allows the team to monitor systems remotely, providing immediate 24/7 support to the operations team, effectively keeping people and plant separate and safe.

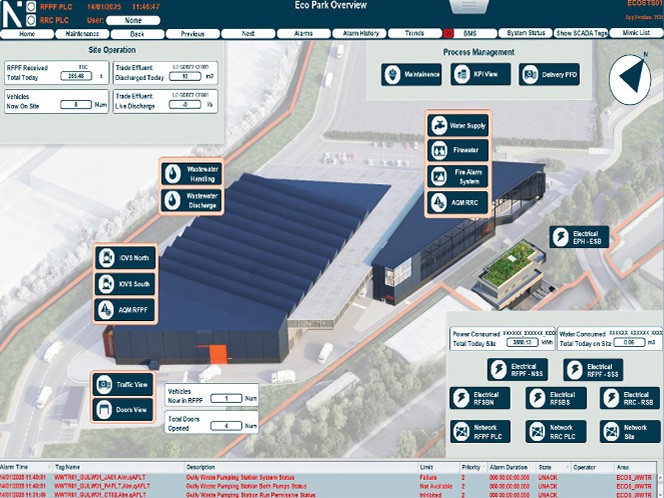

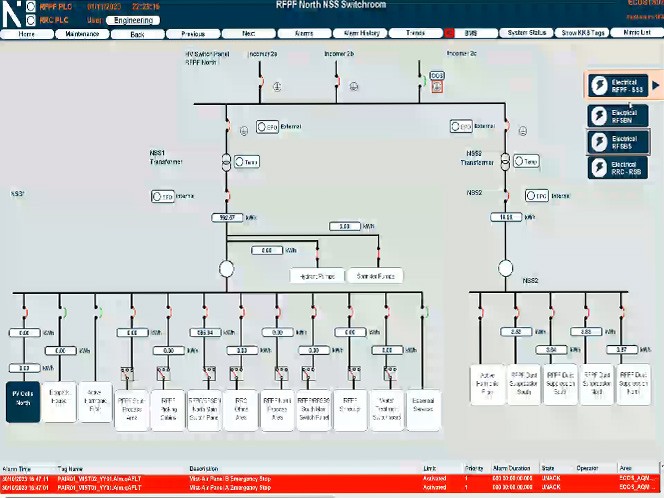

SCADA screens allow the LondonEnergy team to get an overview of systems, with the ability to drill down into particular processes as needed.

SCADA screens allow the LondonEnergy team to get an overview of systems, with the ability to drill down into particular processes as needed.

Fire and odor management with data-led process optimization

Because of the facility’s siloed systems and manual processes, historically it was difficult for operators to access the right information in time to respond effectively to events, equipment failures, or even fires, which are common occurrences in this kind of facility. Now response is immediate. When waste products catch fire, an automatic alarm prompts the team into action before the situation gets out of hand. The AVEVA solution allows the LondonEnergy team to monitor systems and levels in real time as well as investigate events in detail afterward to improve operational processes.

Now the team can also better manage pumping processes for food waste effluent to avoid the build-up of hydrogen sulfide (H2S) gases in manholes, and it can optimize pressure settings for electric and diesel firewater pumps.

Odor is another challenge. Like most industrial facilities in London, the waste facility is close to residential areas. If odors exceed a certain limit, complaints and sanctions ensue. As with the fires, the team can now use the new data infrastructure to optimize processes and equipment to manage these odors, including time limits on how long doors can stay open and the management of air-handling units. Before, odor metrics were driven by council-led complaints, which led to inefficient reaction-based processes. Now, the team can proactively monitor odors before complaints are made. To date, it has received no complaints about the new facility.

SCADA screens allow the LondonEnergy team to get an overview of systems, with the ability to drill down into particular processes as needed.

SCADA screens allow the LondonEnergy team to get an overview of systems, with the ability to drill down into particular processes as needed.

Energy management and wastewater treatment with smarter metrics

The new system has also helped LondonEnergy track and manage its own energy use. During the first month of operations, the team saw they had consumed more electricity than they had anticipated. By looking at the data, they saw that most of their extra energy use came from the integrated ventilation and odor system. In response, they used the SCADA system to reduce the number of fans running during peak and off-peak times, reducing energy consumption by 20%, and saving up to £20,000 worth of electricity. In total, LondonEnergy expects these optimizations to recover £150,000-200,000 in lost earnings per year.

LondonEnergy can better monitor other subsystems at the site as well. In the early months of operations, the facility’s effluent treatment plant required constant monitoring. Blockages to key pumping stations, significant daily fluctuations in wastewater makeup and volumes, and maintenance of key treatment processes all had to be closely followed and managed. Getting this plant up and running optimally with the old system wouldn’t have been possible. With the new system, the team is always on top of this monitoring and are able to manage wastewater flows to consistently meet discharge parameters set by Thames Water.

“Our team of supervisors had a significant challenge in being upskilled to manage the new plant, but the intuitive design of the SCADA/BMS system has made this journey significantly easier. With dedicated on-site support for the first month of operations, and continued remote support, we have been able to follow our ramp-up plan exactly, delivering all key milestones and never dropping any services.”

– Barry Card, RRF Operations Manager, LondonEnergy

Solution

Deployed AVEVA System Platform to unite disparate systems, streamline maintenance, and optimize processes in a centralized operations center

What’s next for LondonEnergy’s waste-to-energy facility

LondonEnergy is excited for the next steps in its digitalization journey, including connecting process and maintenance data to asset, finance, and people data held in Microsoft Dynamics 365 to create a rich visualization of asset usage and condition. The scalability of the solution allows the team to expand the system on-site or apply it to other sites easily. The company plans to work with asset owners, the North London Waste Authority, to construct medium- and long-term asset class strategies aligned to business plans. These plans include moving LondonEnergy’s data infrastructure to the cloud, for even more efficiency and scalability.

Product highlights

AVEVA System Platform, formerly Wonderware

Contextualize operations with responsive, standards-driven, and scalable software for deploying advanced SCADA, MES, and IIoT. Unify people, processes, and assets.