From AI-infused predictive analytics to chatbots that help operators make decisions, AI is changing the way industry works. Large language models (LLMs) like OpenAI’s GPT series, Anthropic’s Claude, and Google’s Gemini are incredibly powerful, but they still have significant limitations, especially when dealing with complex domain-specific topics.

Methanex—the world’s largest producer and supplier of methanol—is overcoming these limitations by integrating internal domain-specific data with an LLM. For this approach to work, Methanex needed a scalable solution that allowed it to securely extract clean operational data. Already an AVEVA™ PI System™ user, Methanex looked to CONNECT, AVEVA’s industrial intelligence platform, to help it take raw data and turn it into AI-driven operational insight.

Challenges

Siloed data and SME knowledge across a globally distributed organization led to slow decision-making

Needed to prevent critical equipment failures and reduce costly downtime

Lack of visibility into operational data hindered improvement efforts and agility

Results

Enabled global collaboration amongst SMEs, vendors and IT professionals, and visualized results from advanced analytics, improving rapid decision-making

Used foundational AI models to predict patterns in AVEVA PI System data, driving significant operational benefits

Deployed customized AI solutions tailored to operational needs

Simplified IT infrastructure integration with other platforms

Using an LLM with internal data for precise predictions

Methanol is an essential ingredient used to produce hundreds of everyday industrial and consumer items such as plastics, cloth, paints, adhesives, and construction materials. It’s also a clean-burning, cost-competitive alternative fuel. To produce methanol, Methanex uses methane as the feedstock, which the company reforms at high temperatures to break it up into the building blocks used to make methanol molecules—hydrogen and carbon monoxide—then combines these molecules in a high-pressure reactor, after which Methanex purifies the methanol, stores it, and ships it globally.

As the world’s largest producer and supplier of methanol to major international markets, with production sites across six countries and 10.6 metric tons of annual operating capacity, Methanex produces a tremendous amount of operational data. But siloed data and SME knowledge had led to slow decision-making. The company knew it needed better visibility into its operational data to prevent equipment failures and reduce costly downtime—and it knew AI could help it get there.

Applications like ChatGPT are powered by LLMs, generating responses based on patterns learned from large-scale training data. However, this approach is less effective with domain-specific tasks, making it challenging for use in industries where data precision is essential. Relying solely on the information from the LLM in these cases can lead to “hallucinations,” incorrect or nonsensical responses that could have serious consequences in an operational setting. Methanex needed an LLM to interact with its internal data sources and provide responses based on this data. So, Methanex’s first step to create these AI models was connecting them securely to clean operational data.

“If we’re [using a foundational AI model] with text, can we do it with time-series data? Yes, we can, and there are many foundational models for that. And the way to access them is with CONNECT.”

—Julio Figueroa, IT Business Relationship Manager, Methanex

Connecting clean operational data with AI models: The CONNECT effect

While Methanex has been using AVEVA PI System for decades, in the last year, it standardized its entire AVEVA PI System platform across its six global production sites. It had clean operational data from its AVEVA PI System—the question became how to connect this data to AI models. The solution turned out to be in the name. CONNECT was the key to successfully bringing together clean operational data and AI models securely and flexibly, specifically with CONNECT data services.

“CONNECT has helped us to significantly simplify the IT infrastructure, lowering the total cost of ownership (TCO). But you know what’s the most important? It has allowed us to free the business to focus on the business problems rather than on IT issues.”

—Julio Figueroa, IT Business Relationship Manager, Methanex

CONNECT, with its lightweight, secure cloud-based platform, simplified Methanex’s IT infrastructure. With configurable visualizations and easily integrated foundational AI models, the team can now predict patterns in AVEVA PI System data and make decisions that optimize production. CONNECT also enabled Methanex to create solutions using AI agents and an operations optimization assistant—solutions that automate time-consuming tasks and offer operators quick, accurate guidance if something goes wrong—further unlocking the power of AI to drive plant efficiency.

Solution

Deployed AVEVA PI System and CONNECT to enable rapid, data-informed, AI-enhanced decision-making—anytime, anywhere.

Visualizing the future of methanol production with CONNECT

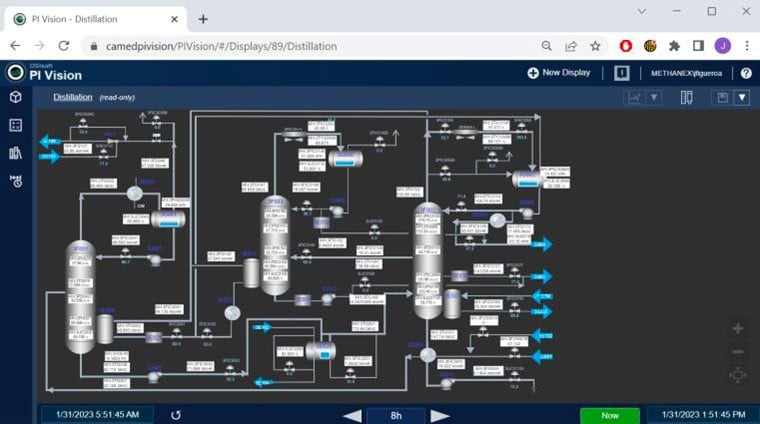

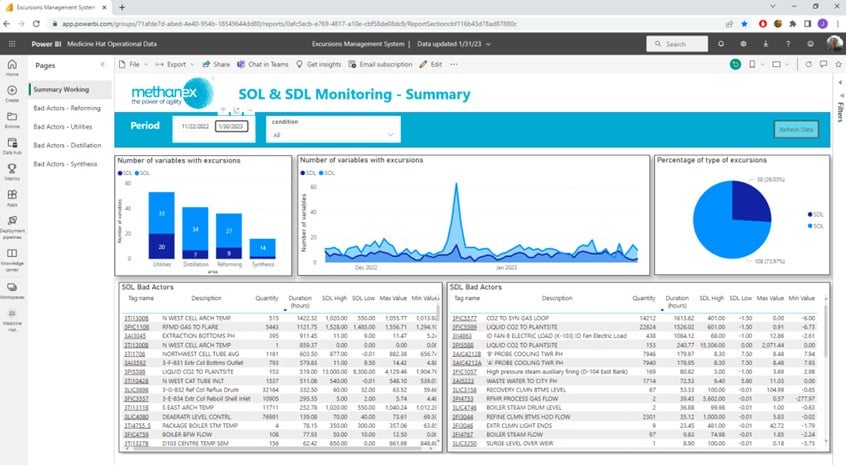

As Julio Figueroa of Methanex says, “You can have great models or great analysis, but you have to build visualizations that are appealing to your users.” There are two types of data consumers at Methanex: operational users, who are well served through AVEVAÔ PI VisionÔ dashboards and AVEVAÔ PI DataLinkÔ, and strategic users, who generally need consolidated data from different sources in different ways. Methanex has found that Power BI serves these users well.

Before, the Power BI Report that Methanex needed to produce required a complex infrastructure that when scaled to six manufacturing sites was labor-intensive to maintain. Now, Methanex connects AVEVA™ PI Server to CONNECT to build PowerBI Reports. A scalable, simplified, easy to maintain solution. This helps Methanex’s strategic users have access to the information they need to collaborate globally and operate more efficiently.

CONNECT enables Methanex to provide different visualizations of operations data depending on the needs of the user.

Building foundational models with CONNECT

For traditional machine learning, you need a lot of clean data to train the model and iterate until the model provides accurate responses. This can be difficult and time-consuming. Even if you get a good result and want to replicate it, it can be difficult to scale.

Foundational models such as OpenAI’s GPT series are already trained on vast amounts of data. These foundational models also exist for time-series data. Instead of having to iteratively train a model until it provides accurate responses, these foundational models allow Methanex to integrate all its internal data, accessed through CONNECT, with a model such as Microsoft Azure’s TimeGen. Using prompt engineering, Methanex can customize these models rather than build them from scratch.

“This has helped us bring the raw data that we’ve collected over such a long time and make it real for our operators, making their lives easier, making our plants more efficient.”

—Franco Branca, Senior Process and Project Engineer, Methanex

Methanex uses a generative pre-trained model designed for time series forecasting and anomaly detection to forecast steam turbine discharge pressure at one of its sites.

Methanex uses a generative pre-trained model designed for time series forecasting and anomaly detection to forecast steam turbine discharge pressure at one of its sites.

Methanex uses these models to detect equipment anomalies before they become operational liabilities. In one example, Methanex used Microsoft Azure’s TimeGen with data accessed through CONNECT to forecast steam turbine discharge pressure at one of its sites. This pressure is a critical indicator of how efficiently the turbine is operating. Using a generative pre-trained model designed for time-series forecasting and anomaly detection with AVEVA PI System and CONNECT data services, operators could see how efficiently this piece of equipment is operating, enabling them to adjust parameters or call in maintenance as needed, and weighted values help operators see what’s influencing behavior trends to understand exactly what’s going on.

AI agents and optimization assistants help operators streamline plant operations

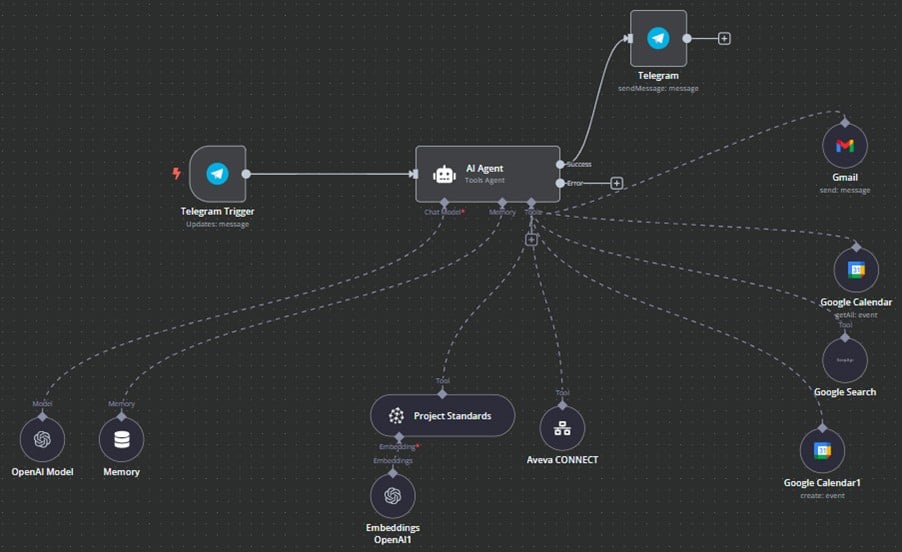

AI agents are software programs in which no business rules are explicitly programmed. Instead, an AI model autonomously selects the tools it needs to complete a task. Methanex customized an AI agent to select what it needs by supplying it with three tools: CONNECT; a document library with procedures, forms, and manuals; and the ability to send an email. CONNECT is integrable with AI agent platforms such as n8n, making it easy for AI agents to access clean operations data.

For example, if an operator asks the agent for the value of one of Methanex’s assets, the agent will choose CONNECT to retrieve that information. If the operator then asks for documentation, the agent will choose the document library. The operator can then ask the agent to send the retrieved information to their email account, so they have it readily available. At a chemical plant, an operator must monitor many different processes simultaneously, often with overlapping alarms. The agent can help the operator prioritize. It can quickly guide the operator to see where equipment behavior is outside the recommended ranges and help prioritize immediate actions, pointing them to the right procedure to follow to optimize operations.

Methanex also trained an AI model to act as an operations optimization assistant. The team takes the process and manual data it has collected over time through AVEVA PI System. Then, it uses a Python-based AI model to receive new input data via CONNECT. Next, the model generates predictions and recommendations. The operator receives visual feedback recommending optimization changes via a custom user interface using CONNECT. And the cycle repeats. The model reviews changes and recommends new adjustments. In this way, Methanex was able to transform raw operational data into actionable insights.

CONNECT is integrable with AI agent platforms such as n8n, making it easy for AI agents to access clean operations data.

CONNECT is integrable with AI agent platforms such as n8n, making it easy for AI agents to access clean operations data.

Some of Methanex’s early conclusions from using these models show that predictions can be improved by including external variables such as weather or inputs from other assets that directly affect the targeted asset. Next steps for the team will include sharing this insight with business users to get their advice on the appropriate variables to use.

By adding CONNECT on top of its AVEVA PI System, Methanex can customize AI solutions that are tailored to its particular operational needs and take advantage of AI-driven analytics, predictive modeling, and real-time monitoring to drive plant optimization. The CONNECT platform and the AVEVA PI System portfolio that Methanex uses are both available through the AVEVA™ PI Data Infrastructure offering.

Product highlights

AVEVA™ PI System™

Collect, aggregate, and enrich real-time operations data for immediate problem-solving and easily deliver formatted data to enterprise applications and advanced analytics.

CONNECT

Our industrial intelligence platform: securely access the broadest and deepest industrial software-as-a-service (SaaS) portfolio enhanced by the power of industrial Artificial Intelligence (AI).