The history of the ball bearing: from logs to bicycles, ancient sketches to advanced technological insights

Posted: October 17, 2025

It takes much less force to roll something than to slide it along the ground, a principle that has influenced innovation in motion for thousands of years. Now, the same principle governs modern, precision ball bearings, components that deliver smooth, dependable motion in almost every moving mechanical process. Without bearings, our industrial world screeches to a halt.

Our Industrial Life

Get your bi-weekly newsletter sharing fresh perspectives on complicated issues, new technology, and open questions shaping our industrial world.

The ball bearing is made up of an inner and outer ring. Between them sit spherical balls that are separated by compartments that allow them to roll freely, thus reducing friction as the rings rotate.

Ball bearings are essential for anything with turning parts. Think high-speed trains, wind turbines and tunnel boring machines; prosthetic joints, medical tools and bicycles.

For large, industrial-scale operations and the motion of most vehicles, ball bearings must be high-quality and capable of withstanding immense pressure and heat. That means bearings need to be built for high performance under extreme conditions. It’s a feat of engineering backlit by a long history.

The technological beginnings of the ball bearing date back thousands of years, spanning cultures and civilizations, all of whom realized that objects could be moved with ease when placed atop something that rolled—whether with logs, wheels or ancestral ball bearings—rather than dragged, carried or slid.

Looking back at the ball bearing’s beginnings

The first innovation in rolling motion may not have been the wheel. In some societies, there is evidence that logs, or other round objects, were set beneath heavy things to transport them more easily.

In Ancient Egypt around 3000 BCE, for example, logs were used to haul large stones to build the pyramids. Writings that demonstrate the development of wheels came with the emergence of Sumeria in Mesopotamia, where an early, wheel-like object manifested as a potter’s wheel.

All around the world, ancient civilizations were finding innovative ways to reduce friction. Drawings from the ancient city of Uruk made in 3000 BCE depict sledges and wheeled vehicles that appear to have been designed for carrying loads. Dozens of wheels, four to five thousand years old, have been recovered from Asia and Europe.

By 500 BCE, vehicles with wheels, not unlike the wheels we use today, were widely in use.

Evidence of the first ball-bearing-like device was recovered from Lake Nemi in the 20th century, located in modern-day Italy at the base of a volcano. In the 15th century, a set of ships that had once been anchored in the inland lake and enjoyed by the ruling class were discovered at the bottom of the lake. Despite people knowing of their existence, the ships weren't recovered until about a hundred years ago.

What appeared to be a kind of turntable emerged from the depths as the ships were hauled to the surface. The object was later dated to between the years 44 and 54 AD.

Inside, the table was fitted with bronze balls, and archeologists hypothesized that it was used to share food at gatherings, to animate statues of their gods or to move goods on and off the ship as part of a crane system. Like rollers in modern ball bearings, there is a notable structural similarity between the Roman turntable and thrust bearings, which are found in the steering mechanism of cars and electric motors.

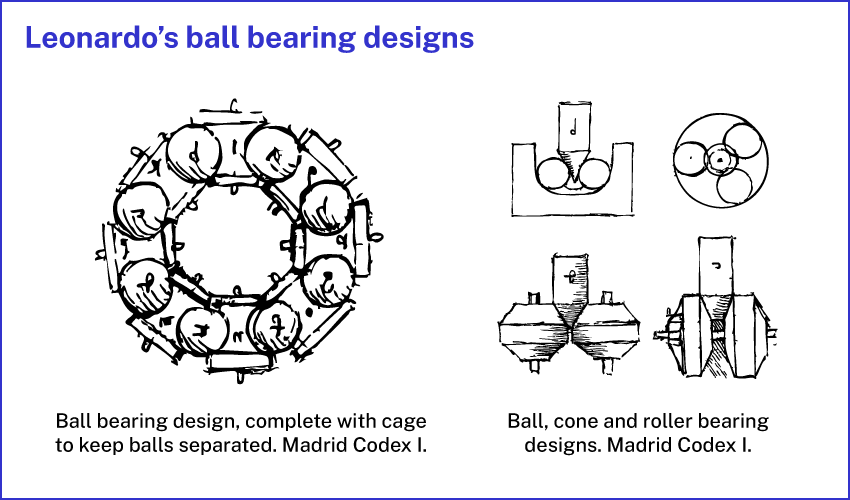

The next big leap in the development of the modern bearing appears in Leonardo da Vinci's sketches: He drew the first model of what resembles the modern ball bearing. To reduce friction, the drawing included cages that separated the balls and allowed them to roll freely.

In the Codex Madrid, da Vinci remarked that if the balls touched, they would be moving in opposite directions at their points of contact, creating friction. “But if the balls or the rollers are kept at a distance from each other,” he wrote, “they will touch at one point only between the load and its resistance...and consequently it will be easy to generate this movement.”

Although his timeless observations provided the foundation for modern bearing development, it took the invention of the bicycle to spur the bearing’s mass production, commercialization and its subsequent improvement.

The first patent related to the ball bearing was issued to a Welsh ironmaster, Philip Vaughan, in 1794 for bearings situated between a carriage wheel and its axle. But bearing patents didn’t proliferate until the late 19th century.

In 1862, the first bicycle bearing patent was issued to A.L. Thirion. In the decades that followed, bicycle pioneers perfected bearings in wheel hubs, crank spindles and steering sockets. At the close of the century, applications for British patents related to ball bearings in bicycles increased from one in 1862 to nearly 150 in the year 1897 alone.

By reducing friction with quality bearings, bikes got faster. And those with the best bearing technology started winning races. Bike makers wanted those winning ball bearings, and newfound demand set the stage for the mass manufacturing of bearings.

Manufacturers began to discover that precision was key: Spheres of different shapes and sizes carry loads disproportionately, which increases friction and wear. Shoddy ball bearings simply won’t last.

The ball bearing industry today

As of this summer, the ball bearing industry was worth over 50 billion dollars, encompassing companies that focus on the production of specialty bearings that have applications in every sector.

Sweden’s SKF, Germany’s Schaeffler, the U.S. group Timken, and three Japanese companies—NSK, NTN and JTEKT—make up 55 percent of the global market for ball bearings.

China is also vying for a more dominant role in the industry by systematically addressing its industrial “choke points.” Historically, Chinese companies have lagged behind their international counterparts in their ability to consistently produce reliable bearings. Part of the reason is that they lacked investment in research and development while other international companies were innovating and establishing their market dominance.

Without the ability to produce precision bearings, China has relied on imports from other countries.

But with an eye to establishing an independent bearing market, Chinese companies are innovating with machine learning. Now, the country is getting closer to producing the essential manufacturing components, like high-quality steel, it lacks.

Image processing tools, like those developed by DeepVision Technology, are also helping Chinese engineers produce high-quality ball bearings at scale. The process of scanning and identifying bearings that don’t meet specifications has increased the number of market-ready bearings from 90 to 97 percent.

Despite China’s progress in precision bearing technology, it still lacks the reputation for having high-quality and long-lasting bearings held by its competitors.

In the race for dominance, companies that strategically employ automation and AI have a competitive edge. Simulation tools, for instance, can determine potential flaws that reduce bearing quality before they are produced. In addition, machine vision and enhanced sensors far more powerful than the human eye can root out the slightest deformity in a ball bearing that would lead to failure over time.

For SKF, a Swedish bearing company, AI helps the company look for new customers, test out new designs and improve supply chain planning.

“The same bearing [from a decade ago] can today be used to do so much more,” Annika Ölme, CTO of SKF, says. “It can take more power. It can take more load. It can actually take more torque. And it’s always evolving everything, from the materials technology down to the actual bearing design and how you test it and how you validate it.”