F. Hoffmann-La Roche, commonly known as Roche, is one of the world's largest pharmaceuticals companies. A leader in healthcare R&D, Roche treats millions of people a year, with billions of patients tested with its diagnostics products. Faced with a complex server landscape and high costs in a commercial data lake, Roche partnered with AVEVA and Capgemini to develop a reliable, cloud-based data platform. It used CONNECT data services to efficiently aggregate and contextualize data from numerous on-premises systems and harness advanced analytics to start improving processes.

“We didn’t expect to have tangible results within such a short time frame. CONNECT data services supported by a strong partner (Capgemini) accelerates the time-to-value of a cloud-based data infrastructure significantly.”

— Heiko Trefzger, Product Manager – Data & Insights, F. Hoffmann-La Roche AG

Challenges

Availability of relevant data for specialized analysts of Roche to optimize processes for drug development and diagnostics

Complex server landscape to aggregate data on a global scale

Large amounts of unstructured data in a data lake

Results

end-to-end data availability

potential reduction of up to 70 servers across the system landscape

advanced analytics revealed opportunities for asset reliability improvements with early anomaly detection

Centralized data sources and systems for streamlined insights

Founded in Basel in 1896, Roche has been innovating in the pharmaceutical and diagnostics space for almost 130 years. Since 1974, it has won 3 Nobel prizes and 44 Prix Galien awards. Developing new medicine is a complex process that is iterative, resource intensive, and requires a high amount of accuracy. Roche produces an incredible amount of process and manufacturing data. The challenge was how to streamline, contextualize, and make this data available for Roche analysts to continue to push the boundaries of medical innovation.

With increasing amounts of unstructured data in a commercial data lake and a complex array of systems and servers, Roche needed a way to simplify its data infrastructure. This goal made it a perfect candidate for AVEVA’s lighthouse program. Through this program, customers can experience the new features of products like CONNECT to see how they perform in the business environment. Through the AVEVA™ PI Data Infrastructure offering, Roche used CONNECT data services to streamline its data infrastructure, then used AVEVA™ Advanced Analytics to optimize centrifuge reliability and bioreactor uptime efficiency.

“We had various data pipeline silos. Now we reunite everything in one, in CONNECT [data services]. We also have unstructured data in the data lake. And now, because everything is inherited from the AVEVA™ PI System™ in CONNECT, we maintain this contextualization and structure throughout the entire pipeline.”

— Gerd Fromm, Product Owner Operational Data systems and applications, F. Hoffmann-La Roche AG

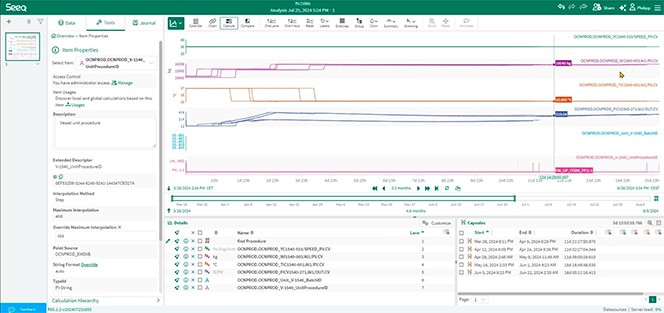

Roche visualizes and analyzes production data through the cloud-native connection between SeeQ and CONNECT.

Roche visualizes and analyzes production data through the cloud-native connection between SeeQ and CONNECT.

Data mesh: Easy integration with less data replication

The first use case the Roche team looked at was what they called “data mesh,” bringing manufacturing data from the plant floor into a centralized cloud environment to make it readily available to Roche’s analysts. They collected data into their AVEVA PI Servers, then fed this data into CONNECT data services. Whereas before, Roche had various data silos and unstructured data in a data lake, now everything was united and the data maintained its contextualization and structure throughout the entire data pipeline.

A major component of the data mesh was integration with existing applications. Just as CONNECT has native integration with Databricks as a built-in feature, the team (“with a little duct tape,” as AVEVA’s Hans-Otto Weinhold said) quickly created integration with Snowflake. Roche used PI SQL Client to pull data in a row column table over to Snowflake, which is used at Roche as a central IT data warehouse, and used Talend as a data pipeline tool to replicate the data into the Snowflake environment to then consume the data with tools like Data IQ. The ease of this kind of integration means that Roche can utilize the tools and applications it already has. Eventually, Roche can eliminate data replication altogether and consume data directly through CONNECT.

SeeQ is another tool Roche uses, mainly for data analytics. By upgrading to SeeQ SaaS, it could take advantage of the product’s native integration with CONNECT. Roche can use SeeQ analytics and AVEVA Advanced Analytics to easily visualize and analyze production data through the cloud-native connection between SeeQ and CONNECT.

Solution

Deployed AVEVA PI System and CONNECT data services for a streamlined data infrastructure, using AVEVA Advanced Analytics for rapid implementation of self-service data analytics.

Advanced analytics for asset reliability and production efficiency

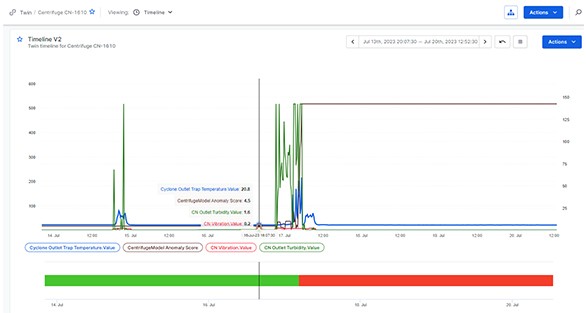

Now that Roche had a centralized cloud environment that could easily integrate with other tools and systems, the team applied advanced analytics for one of its centrifuges. The team focused on Centrifuge CN-1610, looking specifically at the vibration sensor and creating a digital twin of this sensor. Using AVEVA Advanced Analytics, they were able to create a bidirectional stream of sensor data that replicated the asset. A combination of real-time data, factory model data, and machine learning models helped the team detect an anomaly and send the proper alert.

Using a digital twin, Roche can look at multiple complex variables of the centrifuge such as temperature and turbidity to unlock predictive maintenance and prevent costly breakdowns.

Using a digital twin, Roche can look at multiple complex variables of the centrifuge such as temperature and turbidity to unlock predictive maintenance and prevent costly breakdowns.

After verifying this capability, the team moved on to looking at multiple, more complex variables and processes of the centrifuge such as temperature and turbidity. Using historic process data of the last year, along with real-time asset and model data, they were able to see and understand other anomalies. This highly replicable process of anomaly detection allows Roche to increase the reliability of its assets or equipment by alerting the team to deteriorations before a costly breakdown.

Another use case Roche looked at was the production efficiency of one of its bioreactors, Bioreactor V-1540. Again, the team leveraged CONNECT and AVEVA Advanced Analytics to replicate the processes of the bioreactor and visualize the window of production graphically. Using the built-in event visualization of CONNECT, they could see the overall net production time and deep dive into specific variables as needed.

“Here we showed that we have the possibility with out-of-the-box models that exist already in AVEVA Advanced Analytics to rapidly develop some use cases that bring value and are scalable.”

—Lukas Markwalder, Director of Digital Manufacturing and Operations at Capgemini Engineering Switzerland

Roche replicates the processes of the bioreactor and visualizes the window of production graphically.

Roche replicates the processes of the bioreactor and visualizes the window of production graphically.

Simplified IT architecture for scalable results

Roche has plans to continue to simplify its system architecture with CONNECT, getting rid of 70 servers and streamlining its entire infrastructure. This simplified IT architecture means reduced costs, less redundancy, and centralized highly available data. Able to access both CONNECT and AVEVA Advanced Analytics through AVEVA PI Data Infrastructure, Roche quickly realized value from the advanced analytics to optimize centrifuge availability and bioreactor production uptime—demonstrating project results in less than three months, meeting their target milestone of having results to show for Hannover Messe.

As Lukas Markwalder, Director of Digital Manufacturing and Operations at Capgemini says, “Here we showed that we have the possibility with out-of-the-box models that exist already in AVEVA Advanced Analytics to rapidly develop some use cases that bring value and are scalable.” Now Roche can integrate these solutions at other production sites easily, using its unified data infrastructure and applying advanced analytics to create models using existing data and templates it can apply to other machines and processes without additional cost. This accelerated time-to-value means Roche can collaborate and innovate to bring medical and diagnostic solutions to patients faster.

Product highlights

AVEVA™ PI Data Infrastructure

AVEVA’s hybrid operations data platform spans industrial edge, multiple plants and cloud. Use data securely and seamlessly across your enterprise and with ecosystem partners.

CONNECT

Our industrial intelligence platform: securely access the broadest and deepest industrial software-as-a-service (SaaS) portfolio enhanced by the power of industrial Artificial Intelligence (AI).

Advanced analytics

Maximize production efficiency, improve quality, energy efficiency, and throughput with cloud-based predictive and prescriptive insights.

AVEVA™ PI System™

Collect, aggregate, and enrich real-time operations data for immediate problem-solving and easily deliver formatted data to enterprise applications and advanced analytics.