The German chemicals company, Wacker Chemie, has been innovating for over 100 years. To reach its targets of €10 billion sales by 2030 and net-zero emissions by 2045, it needed to run concurrent engineering projects more efficiently. So Wacker Chemie set out to construct and implement a centralized data environment with AVEVA™ Unified Engineering that would enable collaboration and concurrent engineering across its global teams.

Challenges

Inconsistent and out-of-date 3D plant models hindered operational efficiency

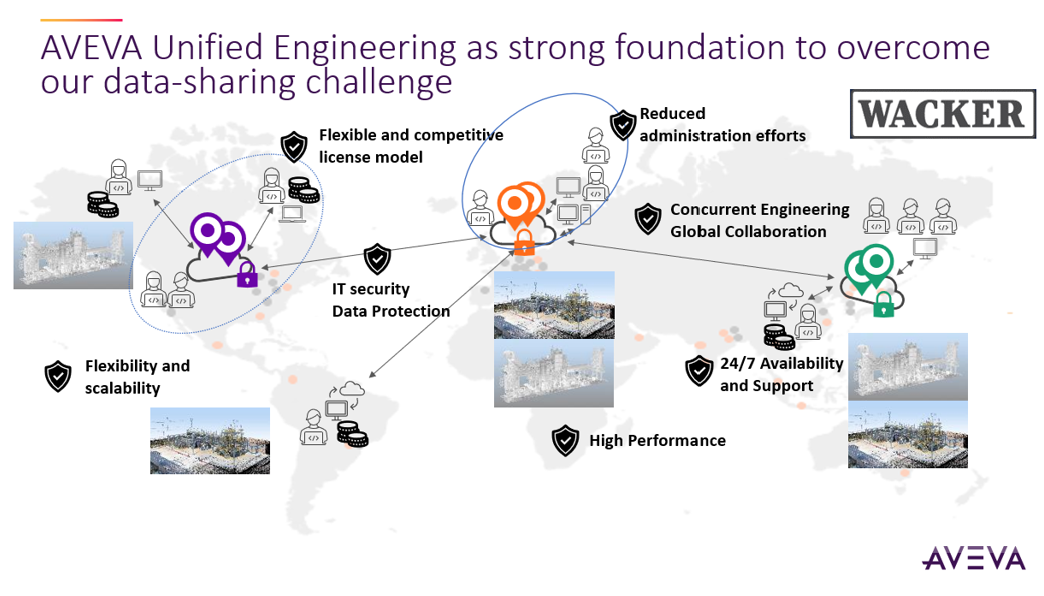

Decentralized data hosting required excessive administration and engineering effort to share plant models

On-premises servers required manual updating and reconciliation

Results

25%

reduction in administration efforts

40%

quicker 3D project ramp-up due to administration savings

cloud-based data storage increased IT security

improved project flexibility and scalability

The promise of concurrent engineering

Wacker Chemie produces a diverse array of biosolutions, silicones, polymers and polysilicons for a wide variety of commercial sectors, from the automotive and transport industries to the industrial biotechnology sector. Working globally and across so many industries and sectors simultaneously, Wacker Chemie knew it could reap huge benefits from increased efficiency if it could more seamlessly integrate its diverse set of stakeholders and external contractors in its parallel projects.

Before it adopted AVEVA Unified Engineering, Wacker Chemie’s traditional installation of on-premises servers required manual updating and reconciliation. This meant that there could be different versions of the 3D plant models across the different stakeholders involved in a project. To ensure that consistent data was readily present, the teams relied heavily on administration assistance to maintain the data across the multiple locations, increasing project time and cost.

After Wacker Chemie adopted AVEVA Unified Engineering, administrators no longer had to work on multiple models on multiple systems, but could simply operate directly on the single model in the cloud. As a result, the company can implement large capital investment projects with unprecedented speed.

“We deployed AVEVA Unified Engineering to enable central data hosting, concurrent engineering, global access and flexible scaling.”

–Thomas Mairhofer, Director of Digital Engineering Applications, Wacker Chemie

The high performance of the 3D engineering environment

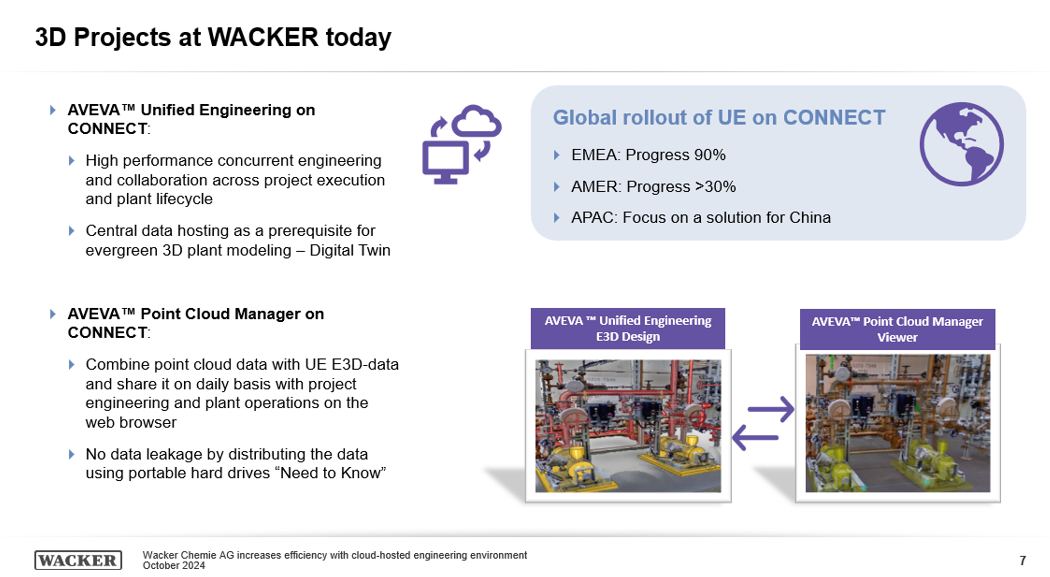

By the beginning of 2024, Wacker Chemie had successfully migrated 90% of its new projects in Europe to AVEVA Unified Engineering on the cloud. The platform was able to handle parallel projects such as optimization, maintenance, and shutdown procedures. It could also successfully resolve many of Wacker Chemie’s data-sharing problems by allowing for global high-performance concurrent engineering and collaboration.

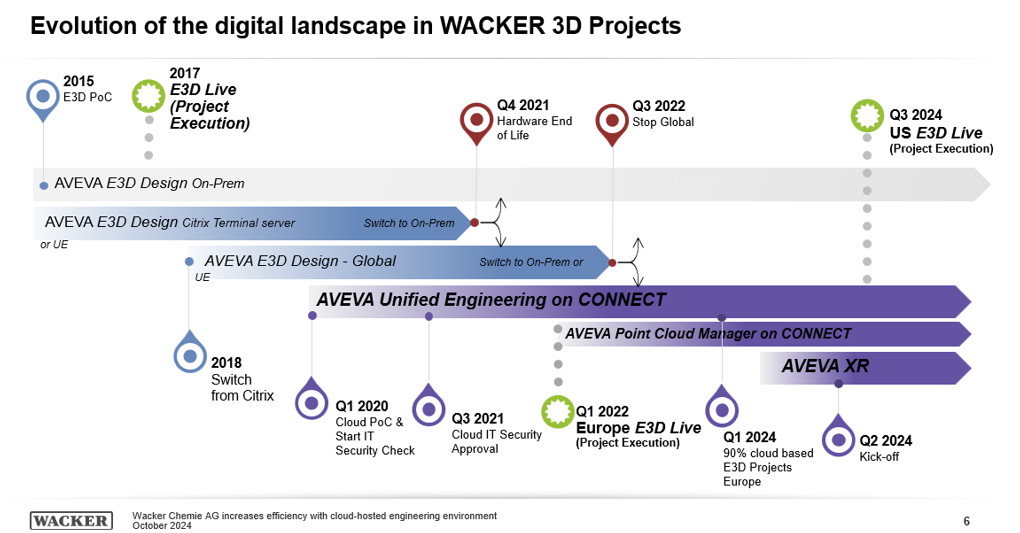

Wacker Chemie chose AVEVA Unified Engineering after its experience with AVEVA™ E3D Design on-premises since 2015 and AVEVA E3D Design on AVEVA Global as an intermediate solution between 2017 and 2021. Working with AVEVA, Wacker Chemie has been able to create a cloud-hosted digital engineering environment that enables it to unleash the power of concurrent engineering. It now can benefit from new flexibility and scalability of projects and can integrate new designers and contractors more quickly than ever. The tools have led to a 25% reduction in administration efforts, and mean that Wacker Chemie can ramp-up 3D projects 40% quicker due to administration savings.

The business still has a small percentage of information not on the cloud—things such as third-party tools and metadata for pipes—that it hopes to unite in its single cloud environment engineering database.

Solution

Adoption of AVEVA™ Unified Engineering and AVEVA™ Point Cloud Manager on CONNECT for efficient global cloud-based data sharing. Planned adoption of AVEVA Extended Reality (XR) to support plant design review.

Wacker Chemie already had a relationship with AVEVA when it began searching for a cloud-based data hosting solution—and found the right one for enterprise with AVEVA Unified Engineering

Wacker Chemie already had a relationship with AVEVA when it began searching for a cloud-based data hosting solution—and found the right one for enterprise with AVEVA Unified Engineering

A secure cloud-based foundation for a digital twin

The company conceives the cloud-based data sharing as the prerequisite for Wacker Chemie’s first digital twin—an evergreen 3D plant model. By combining AVEVA Unified Engineering and AVEVA Point Cloud Manager on CONNECT, Wacker Chemie can reference laser scans both on premises and in the cloud. The central hosting enables Wacker Chemie to gather together the regularly updatable and detailed data that is needed for a true digital twin.

Wacker Chemie has also benefitted from cloud-based data storage’s increased IT security. Now that it can easily grant its contractors and stakeholders access to the data on the cloud, the company no longer has to use portable hard drives to allow for multiple stakeholders to engage project models. With everyone synced on one place in the cloud, Wacker Chemie is both more efficient and more secure—as its teams have visibility on its data at all times. With this streamlined data management and access, colleagues can find the information they need quicker, resulting in faster decision-making.

“AVEVA Unified Engineering is the right solution for efficient and performant data sharing with stakeholders and strategic partners in the global engineering supply chain. The solution is an important pillar for achieving our strategic goals—growth and sustainability.”

–Joey Greear, Engineering Manager, Process Control and Digital Engineering Applications, Wacker Chemie

With the cloud hosting of AVEVA Unified Engineering, Wacker Chemie has been able to reduce administrative efforts necessary for floabl collaboration in its concurrent engineering projects

With the cloud hosting of AVEVA Unified Engineering, Wacker Chemie has been able to reduce administrative efforts necessary for floabl collaboration in its concurrent engineering projects

Because of the new security and efficiency benefits, Wacker Chemie is now focusing on rolling out its new model in the United States. It has already begun beta testing at its facility in Charleston, Tennessee and expects the new cloud-based model to facilitate the improved collaboration and more evergreen modeling from which its European teams are already benefitting. Wacker Chemie is also looking forward to collaborating with AVEVA to expand its cloud-driven use of AVEVA Unified Engineering to the Asia and Pacific region, where it hopes to realize similar efficiency gains in its operations in China.

Wacker Chemie has also recently introduced AVEVA™ XR, which it hopes will allow it to use virtual reality for plant design review, enabling colleagues to see and review models in 3D. In the future, Wacker Chemie hopes virtual reality will also help with training, allowing it to connect multiple people in a virtual reality environment.

Wacker Chemie has used AVEVA Unified Engineering’s cloud-based data hosting to create the foundation for an evergreen digital twin—and continues to seek out further applications

Wacker Chemie has used AVEVA Unified Engineering’s cloud-based data hosting to create the foundation for an evergreen digital twin—and continues to seek out further applications

Product highlights

Engineer and collaborate across all project phases and multi-discipline teams in a single data-centric platform.

Formerly Known As AVEVA Everything 3D

AVEVA E3D Design is a 3D design software used in process plant, marine and power industries. It helps create designs and drawings and reduce costs and project risks.

Formerly Known As AVEVA LFM

Capture the 3D baseline of your existing brownfield asset in a simple, accessible and secure workflow with AVEVA Point Cloud Manager.