Bruce Power already operates the world’s largest nuclear facility, but it plans to grow its operations even bigger. To succeed in three planned expansion projects, the Ontario-based clean energy leader needs to deliver on time and on budget, all while ensuring more efficient, productive operation in the years ahead. With AVEVA's help, and a suite of AVEVA solutions, Bruce Power launched a phased approach to digital transformation.

Challenges

To fulfill its investment deal structure, Bruce Power needed to reduce project timelines and costs

Outdated tools and document-centric processes restricted further gains in efficiency

Needed tools that could improve both project delivery as well as the operation of the assets over time

Results

1000

employee hours saved so far in avoided data retrieval

15%

savings in avoided repeat walkdowns and field checks

30%

savings in execution thanks to improved design quality

50%

savings in costs and schedules at engineering change closeout

From delivery to operations and maintenance

With eight reactor units, and a total installed capacity of 6,555 megawatts, Bruce Power is already the world’s largest operating nuclear facility. That doesn’t mean it’s run out of room to grow. The Ontario-based clean energy leader has three key expansion plans on the horizon. First, it plans to expand the lifespan of six existing units to 2064 and beyond. Next, with its recently deployed isotope production system, Bruce Power plans to produce more medical isotopes like lutetium 177 and Cobalt 60 (commonly used to fight prostate cancer and to clean medical equipment respectively). Finally, Bruce Power is looking to expand in the traditional sense by adding another 4,600 megawatts of generation capacity to its site through new builds.

To succeed in all these new expansion opportunities, Bruce Power, by its investment deal structure, must deliver each new iteration of refurbishment faster and cheaper than the last. “In order for us to meet those targets,” says Patrick Desbiens, Program Manager of Digital Engineering at Bruce Power, “we have to drive down project delivery costs and duration while achieving new efficiencies for operations and maintenance to sustain those assets over time.”

Fortunately, all those goals begin with a common strategy: driving digital transformation with data-centric processes. To devise that strategy, and put it into action, Bruce Power partnered with AVEVA.

“It was important for us to partner with someone who had that scale and ecosystem to meet all our needs, and that’s where we selected AVEVA.”

“It was important for us to partner with someone who had that scale and ecosystem to meet all our needs, and that’s where we selected AVEVA”

-- Patrick Desbiens, Program Manager of Digital Engineering at Bruce Power

A new digital toolkit for a data-centric approach

At the outset of its new digital transformation project, the team at Bruce Power saw that they had achieved just about all the efficiency gains they could with their traditional approach, which was built on document-centric processes and outdated tools. “Some of the tools we’re using today,” says Desbiens, “are actually the same ones that were used to build the station.” To go further, Bruce Power needed a new approach, enabled by a new data-centric toolkit.

With AVEVA’s help and an integrated suite of AVEVA solutions, Bruce Power launched its digital engineering initiative: A modular, phased approach to digital transformation, focusing first on high-value optimization targets.

“It’s quite ambitious,” says Desbiens. “It covers a lot of functionality across multi-discipline processes.” It spans from the plant wiring configuration tool to the introduction of 3D models into processes and the transition to digital, intelligent deliverables.

Solution

Deployed an integrated suite of AVEVA solutions, including AVEVA™ Asset Information Management, AVEVA™ Point Cloud Manager, AVEVA™ Unified Engineering, AVEVA™ PI System™ and CONNECT to streamline operations, reduce project costs, and improve efficiency.

Connecting the dots

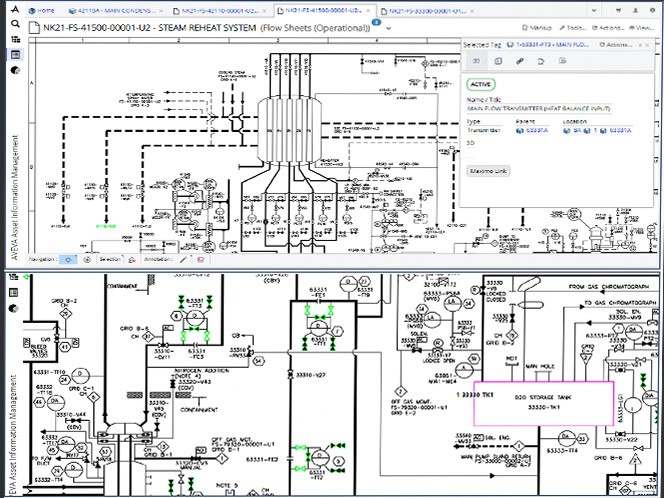

Bruce Power embarked on its new digital engineering initiative with an enterprise-wide deployment of AVEVA Asset Information Management to connect all the data from its brownfield units and reduce the time employees spent searching for information. Connecting information from five sprawling systems into just one centrally accessible hub is no small task; in all, this information includes 720,000 equipment codes, 4,000 operational flowsheets, about 1.7 million documents, 30-plus datasets, and 40,000 tags from AVEVA PI System.

Digitized flowsheets, which are used across the organization and across roles, now serve as a key entry point into Bruce Power’s new system. Already, the company’s new system has over 1,800 unique users and has helped them save over 1,000 hours of searching to date. “We wanted this to enable users to find the right data at the right time for timely decision-making,” says Desbiens.

Bruce Power has digitized over 1.7 million documents, such as the flowsheet above, using AVEVA Asset Information Management.

Bruce Power has digitized over 1.7 million documents, such as the flowsheet above, using AVEVA Asset Information Management.

Before its digital transformation, Bruce Power’s users were required to open every single location in its legacy tools and attach the associated documents manually, which was very labor-intensive. “When you’re relying on people to manually do that,” Desbiens says, “you’re missing things.” Now, with AVEVA Asset Information Management, the team is automating tag-to-document relationships. “Issue your documents,” Desbiens says, “and next time you open [AVEVA Asset Information Management], those relationships will be there.” [AVEVA PI System] is also a big benefit here.” Users can view real-time operational data from AVEVA PI Vision directly within the AVEVA Asset Information Management environment, streamlining access to live process insights.So far, automating this process has helped Bruce Power save 50% in costs and schedules at engineering change closeout.

“We wanted this to enable users to find the right data at the right time for timely decision-making.”

—Patrick Desbiens, Program Manager of Digital Engineering, Bruce Power

More sophisticated modeling processes for higher-quality work

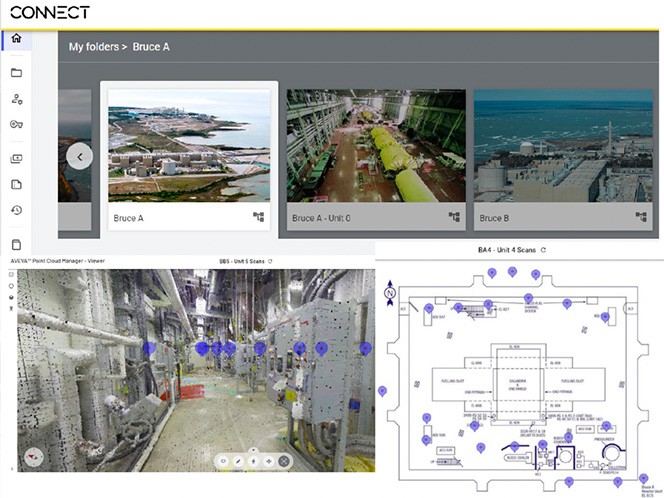

The digital engineering team at Bruce Power deployed AVEVA Point Cloud Management via CONNECT. The digital engineering team worked together with the refurbishment teams and other project teams to define a laser scanning standard. Now, project teams can continue completing scans, which are then sent to a central location where the digital engineering team can stitch them all together into one virtual station.

Within six months of deployment, Bruce Power has scanned seven out of the eight reactor units and uploaded 15 other projects—approximately 8.5 terabytes of data all together. In the past, this wealth of point cloud data was accessible only to a select few at Bruce Power, but now, through CONNECT, Bruce Power can make it accessible to other parts of the business. Operations teams can use the data for safety pre-job briefs and field teams and engineers can use scan data to complete tasks that once required physical travel (and extensive coordination) to hazardous, radiological areas.

So far, the new solution has helped Bruce Power achieve 15% time savings in avoided repeat walkdowns and field checks. More accurate scans have also improved design quality for a 30% savings in execution.

Using AVEVA Point Cloud Manager, Bruce Power has modeled seven of its eight reactors from laser scan data.

Using AVEVA Point Cloud Manager, Bruce Power has modeled seven of its eight reactors from laser scan data.

A future-ready digital foundation

AVEVA Asset Information Management has already helped save employee time. Its integration with AVEVA PI System has further enhanced operational intelligence by embedding AVEVA PI Vision displays into engineering and maintenance workflows. Bruce Power expects this integration to help expand the use of AVEVA PI Vision across its departments, reducing delays and improving situational awareness. AVEVA Point Cloud Manager has helped improve work quality, but Bruce Power’s digital engineering initiative is only just beginning.

Next, the power leader plans to roll out AVEVA Unified Engineering and AVEVA Enterprise Resource Management to promote the full workflow of engineering changes to projects and brownfield data, which the team expects will continue to deliver more time and cost savings. “And that’s exciting for us as a company,” Desbiens says, “because that means reliable, carbon-free base-load power and medical isotope production for decades to come.”

Product highlights

AVEVA™ PI System™

Collect, aggregate, and enrich real-time operations data for immediate problem-solving and easily deliver formatted data to enterprise applications and advanced analytics.

AVEVA™ Asset Information Management

AVEVA AIM connects engineering, operations, and maintenance teams with real-time access to validated data - boosting reliability and reducing rework

CONNECT

Our industrial intelligence platform: securely access the broadest and deepest industrial software-as-a-service (SaaS) portfolio enhanced by the power of industrial Artificial Intelligence (AI).

AVEVA™ Point Cloud Manager

Formerly Known As AVEVA LFM

AVEVA™ Point Cloud Manager is a cloud-enabled 3D data capture solution that facilitates production and visualization of scalable, reliable reality capture data sets.

AVEVA™ Unified Engineering

AVEVA Unified Engineering is a data-centric engineering environment. Engineer and collaborate across all project phases and multi-discipline teams in real time.