Biosurfactants: the future of personal care and cleaning products?

Posted: June 30, 2025

In 2023, the sustainable cleaning product company Ecover launched a pair of limited-edition products to demonstrate how the industry might reduce its ecological footprint by using food waste. The “Too Good to Waste” multi-surface cleaner and toilet cleaner boasted a series of eye-catching ingredients: its lemony fragrance came partly from rescued fruit, while leftover alcohol from the booze-free beer production provided the necessary ethanol. Yet the most vital factor may well have been the use of surfactants—specialized chemical compounds used widely in cleaning—made from potato peels using an environmentally-friendly fermentation-based process.

That special ingredient was provided by AmphiStar, a Belgian start-up that has since publicly launched its own line of waste-based “biosurfactants” designed for use in cleaning and personal care products. If the technology takes off, biosurfactants could offer huge ecological benefits in comparison to conventional surfactants, thus helping to reduce waste and carbon footprint in many different industries.

Our Industrial Life

Get your bi-weekly newsletter sharing fresh perspectives on complicated issues, new technology, and open questions shaping our industrial world.

What are biosurfactants and how are they made?

Surfactants—literally “surface-active agents”—play a key role as additives in a wide range of cleaning and personal care products, as well as in industries like petrochemicals.

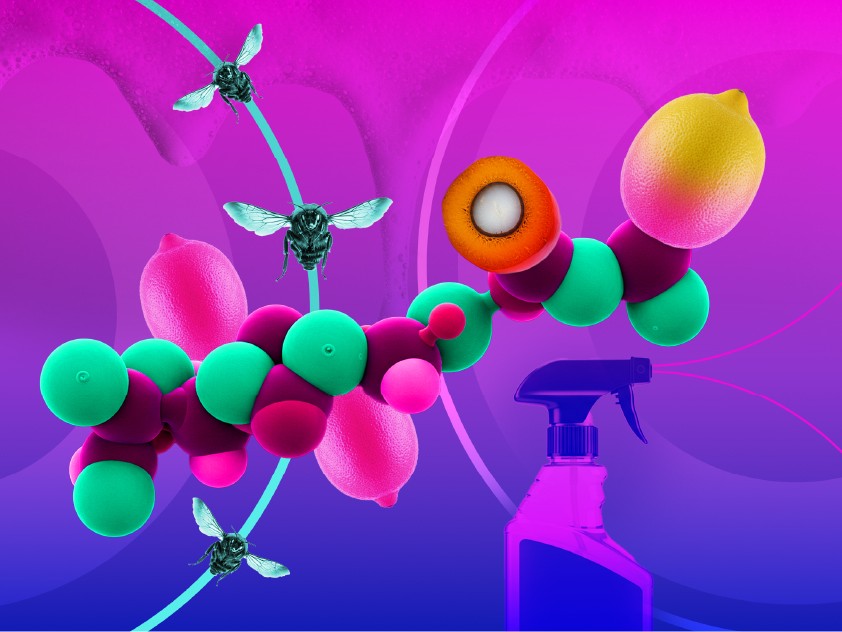

In terms of chemistry, surfactants are molecules that possess both hydrophilic (water-attracting) and hydrophobic (water-repelling) elements. They are therefore able to operate at the interface of water and oil, usually either by holding oil-water combinations together or by making it possible to remove dirt and grease. Surfactants can reduce surface tension, allowing liquids to spread more effectively. They allow moisturizers and cleaning agents to work; they have also been used in oil spill response.

The majority of surfactants today are made petrochemically from fossil fuels. As such, interest has been growing in ways to produce surfactants from different feedstocks, particularly renewable raw materials. Surfactants produced partly or entirely from plant-based inputs are known as bio-based surfactants. Ingredients marketed under this tag might use inputs that are more or less sustainable—a decent chunk of the market uses palm oil—and they are not necessarily 100% bio-based. The EU initiative Circular Bio-based Europe estimated in 2022 that only 4% of the global surfactant market consists of fully bio-based products.

In recent years, momentum has been growing behind biosurfactants, a set of ingredients that promise even greater environmental advantages. Whereas bio-based surfactants are still produced via chemical synthesis, biosurfactants are typically biosynthesized by living organisms such as bacteria, yeast and fungi using renewable raw materials, byproducts, or waste as inputs. The production of biosurfactants usually involves a fermentation process, whereby microbes—often genetically modified—consume the bio-based inputs and release surfactant ingredients as a result. AmphiStar, for instance, has used the yeast Starmeralla bombicola, originally isolated from bumblebees, to produce over 25 distinct biosurfactant ingredients out of biomass like discarded food waste. Doing so avoids the need for traditional chemical processing.

“Precision fermentation allows you to upcycle waste and industrial side streams to valuable active compounds that are locally produced, with no direct land use and with a mild production process (low temperature, low pressure, no toxic catalysts) to make products that are biodegradable and not toxic,” said founder Bernd Everaert.

Biosurfactant-based products are becoming market ready

Biosurfactant producers argue that, in addition to using more eco-friendly materials, their milder methods of production also contribute to a lower overall carbon footprint compared with even bio-based conventional surfactants. Biosurfactants can also offer higher levels of biodegradability in addition to reduced toxicity and less harm to aquatic organisms.

Obstacles remain for biosurfactants’ widespread adoption, not least in terms of production cost competitiveness. Yet sustainability-oriented shifts in the personal care, cosmetics and cleaning industries are leading many—both established firms and startups—to bet on a technology that was described by Chemical & Engineering News last year as “trending.”

Last year, Evonik announced that its industrial-scale facility for sustainable biosurfactants in Slovakia had manufactured its first product. The firm’s rhamnolipid biosurfactants, produced from renewable corn feedstocks using an IP-protected fermentation process, are slated for use in the cleaning and personal care industries. “Our high-performance rhamnolipids are setting a precedent, not only at Evonik, but as part of a broader sustainable chemicals revolution,” said Johann-Caspar Gammelin, president of the company’s Nutrition & Care division.

The UK biosurfactant specialist Holiferm, which uses fermentation on 100% renewable feedstock, claims its products have an environmental footprint around half that of traditional surfactants. Since 2022, Holiferm has been working with Sasol Chemicals to develop and commercialize biosurfactant applications; they have also signed a strategic technology agreement with BASF for applications in home care, personal care and industrial formulators. The firm has successfully integrated AI into its production process in order to track systems and maximize efficiency.

In Canada, the startup Dispersa recently closed $5.8 million in seed funding to scale up production of their biosurfactant ingredients that use food waste such as discarded sugar, oil and grease from fast food restaurants. While Dispersa is currently geared towards the cleaning industry, the company hopes to see its ingredients replace conventional surfactants much more widely. “Creating the greatest impact for us means finding our ingredient in as many industries as possible,” explained founder Nivatha Balendra.

AmphiStar continues to scale, as well, having recently announced a strategic partnership with the US-based surfactant producer Kensing to bring the firm’s biosurfactant range to the North American personal care market. With a 100% waste-based offering and the promise of continuous cost-effective production, AmphiStar COO Sophie Roelants has described the firm’s personal care and cleaning applications as “a significant breakthrough in the shift towards fully sustainable surfactants.”

If that breakthrough works out at scale, it may well change the industry for good—and not just as a cosmetic improvement.