$1 trillion to be unlocked in Digital Transformation?

Posted: September 10, 2019

Rising trade and geopolitical tensions are heightening volatility in the oil market with crude prices swinging widely in recent years. Given the increased volatility and expectation of a lower crude price environment, oil and gas companies are accelerating their Digital Transformation initiatives as a means to reduce operational costs and gain competitive advantage amid market chaos. According to a recent World Economic Forum report , Digital transformation in the Oil and Gas industry could unlock approximately $1.6 trillion of value for the industry, its customers and wider society while creating around $1 trillion of value for Oil and Gas firms. Digital initiatives, if well executed, can unleash enormous opportunities in value creation.

Digital Transformation begins with Data, data and data

Data is the foundation of every Analytics and machine learning applications. Data is the ‘raw material’ that feeds into analytics and A.I. and, in turn, enables data modelling to optimise process, to predict machine failures before they happen and to support decision making. Tagging operating assets with low quality and noisy data at the start of the process is likely to generate inferior or inaccurate results at downstream, reducing the value that can be extracted from the data. Therefore, ensuring a robust technology infrastructure to store, manage and contextualize data is first steps towards execution of Digital Transformation initiatives.

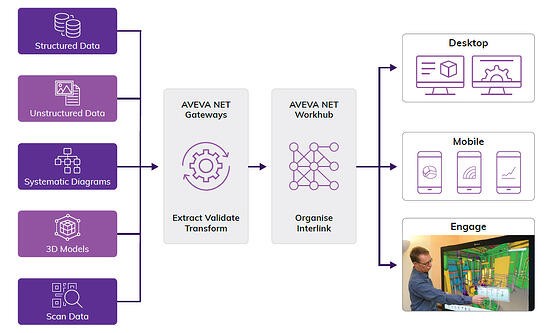

Data from disparate sources to Predictive Analytics

At the field level, the PLC/RTU collects and feeds data from instrumentations or IOT devices to SCADA or/and Historian. This data is then tagged to specific assets or process models with all the necessary attributes and engineering documentation– such as geometry, layout, connectivity of key components and process data, and other business and safety-critical engineering and design information. Combined with a robust information gateway, the engineering information and data can be further validated for accuracy against known standards and this acts as a data validation layer to ensure that all data meet the correct standards throughout the asset lifecycle. With this, field operators can easily assess up-to-date operating, maintenance work record and engineering information of an asset that have been flagged for attention with a search tag. This helps them identify the issues and determine the appropriate actions quickly to prevent production outages.

A good illustration is the ADNOC’s Panorama Digital Command Centre that provides operational visibility across the entire hydrocarbon value chain – from exploration to distribution of products, breaking down information silos and providing real-time operational insights based on a single, trusted view. This not only improves operational efficiencies, but also uncovers new pathways to optimize performance.

Predictive Analytics for Data Modelling and Prediction

Next, the real-time operations data is fed into predictive analytics and artificial intelligence with the ultimate goals of optimizing overall production, process conditions and even predicting failures ahead of time. Predictive Analytics enables empirical multi-variate modelling of rotating equipment performance – such as pump, compressor and turbine - using advanced pattern recognition and machine learning algorithms to identify and diagnose any potential operating issues days or weeks before failures occur. Operating models, including past loading, ambient and operational conditions, are used to create a unique asset signature for each piece of equipment. Real-time operating data is then compared against these models to detect any subtle deviations from expected equipment behavior. This allows more effective and reliable monitoring of different types of equipment at remote site, improving equipment reliability and workforce efficiency by reducing field visits.

The early warning notification allows reliability and maintenance teams to assess, identify and resolve the problems, preventing a major breakdown that can cost companies millions of dollars in production slowdowns or even stoppages.

Embarking on a journey with sustainable long-term results

Digital transformation allows companies to create new capabilities, new business models, and innovate ahead of their competition. It is a journey through deployment of technology and driving behavioral change in workforce – changing when, where, which, and how work is performed and evolved. Making the transition successfully can be profoundly rewarding for companies, since even slight improvements in asset utilization can result in huge gains in revenue and cash-flow.

Are you ready to take the first steps to enable Digital Transformation in your enterprise to gain competitive advantage today?

Visit Unified Operations Center for Oil and Gas to learn how to activate your digital transformation plan and take operational excellence to the next level.

Related Blog Posts

Stay in the know: Keep up to date on the latest happenings around the industry.