SCADA software and SCADA solutions

SCADA software is used within a SCADA system which can be spread across different locations, sometimes over a wide geographical area, or contained within a single facility. SCADA is extensively used in the process control industry, drinking water delivery systems, wastewater collection systems, pipelines and a range of other manufacturing processes. Learn more in AVEVA’s guide to understanding SCADA.

But SCADA is not an end in itself.

Maintaining efficiencies and identifying problems as soon as they occur are just some of the ways SCADA systems can support your operation. They can also improve productivity, quality and profitability while keeping costs at a minimum.

SCADA is a significant long-term investment and choosing the right system is vital.

How SCADA software can benefit your operation

The best SCADA software will be of lasting value to your organization, helping you stay ahead of your competitors and grow. The best software should improve production quantity and quality, reduce costs, minimize waste and be completely reliable.

SCADA software should also deliver efficiency gains across different systems in your organization, as well as improve the performance of your plant and equipment. To bring value to your organization, SCADA systems need to lengthen the lifecycle of your assets and reduce your maintenance costs.

AVEVA’s SCADA software solutions tick all those boxes.

AVEVA’s world leading SCADA software

AVEVA has a long history and unbeatable track record in delivering SCADA software solutions to organizations large and small. We offer a winning strategy for meeting complex and evolving automation requirements, as well as solutions for more straightforward operations.

It’s almost impossible to predict your long-term technology requirements in this era of constant innovation and rapid change. That’s why our solutions are designed to evolve with technology and grow along with your business.

Our solutions help protect your engineering investments, improve machine reliability and uptime, improve operational efficiency, productivity and reliability.

Key benefits of AVEVA’s SCADA software

Operational Excellence

World-leading capabilities and innovative user experience empower operators to meet complex operation requirements.

- Drive standardization with rapid development and improve lifecycle management.

- Create a single common information model.

- Continuous operational improvement without impacting live production system.

- Open standards supported such that communications integration is simple.

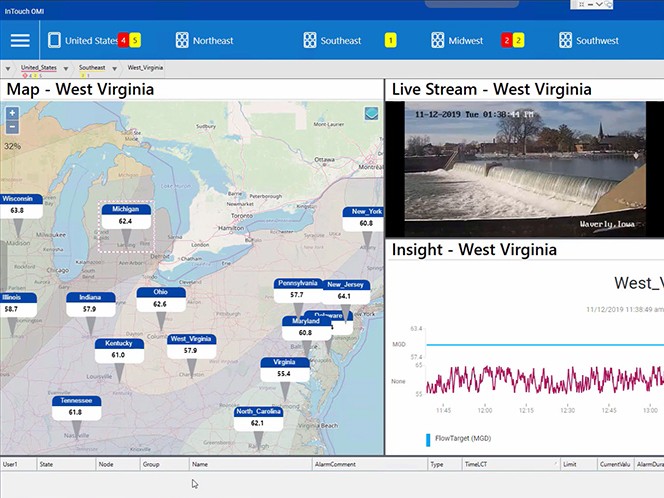

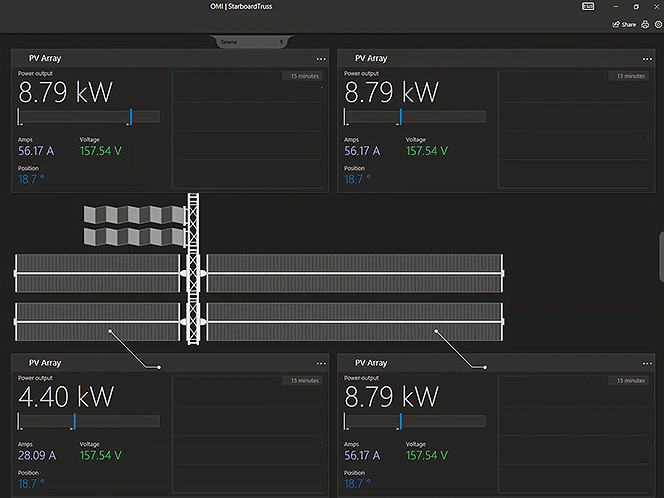

Powerful Visualization

A strong legacy of powerful visualization underpins our SCADA strategy for industrial customers.

- Uncluttered visualization of the equipment, presenting the operator with action-able information with advanced alarming and analysis.

- Seamless on the fly changes to operator visualization to do scripting or programming.

- Real-time, holistic situational context helps improve efficiency and facilitate timely corrective action- see our HMI and SCADA Design Fundamentals whitepaper

- Displays focus on situational awareness principles, including control room management (CRM).

Trusted solutions

Our SCADA software is highly secure, scalable and offers real-time supervisory control. It’s trusted to manage critical infrastructures around the world. Find out more about SCADA security.

- Open, hardware vendor agnostic technology that supports a best of breed software

- Highly robust system security that protected from unauthorized access

- Robust high reliability with redundant failover system

- Built-in monitoring of communications and overall system health diagnostics

- Change management with version control, audit trail and the ability to rollback

Selecting AVEVA as Your Industrial Software Provider

AVEVA has a long history in providing Supervisory Control and Data Acquisition software and offers a winning strategy for meeting complex and evolving automation requirements while protecting engineering investments. Whether you are looking to start small or implement a comprehensive system, our software solutions provide operational excellence within industrial automation and across our full Engineering, Operations and Performance software portfolio.

AVEVA System Platform, formerly Wonderware

Contextualize operations with responsive, standards-driven, and scalable software for deploying advanced SCADA, MES, and IIoT. Unify people, processes, and assets.

AVEVA™ Plant SCADA

Formerly Known As Citect SCADA

AVEVA Plant SCADA (formerly Citect SCADA) is the leading flexible, high-performance supervisory control and data acquisition (SCADA) system for industrial-process and infrastructure customers.

AVEVA Enterprise SCADA

Formerly Known As OASyS

AVEVA™ Enterprise SCADA, an enterprise pipeline management system, is the foundation for real-time pipeline operations optimization from edge to enterprise.

Discover latest news and resources

Check out the latest news, and success stories