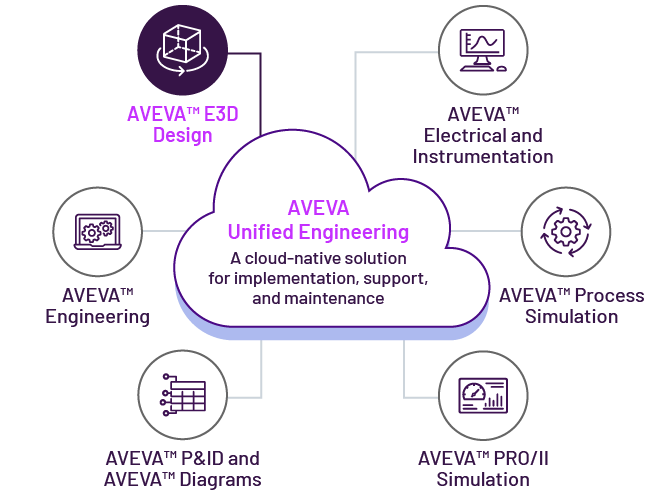

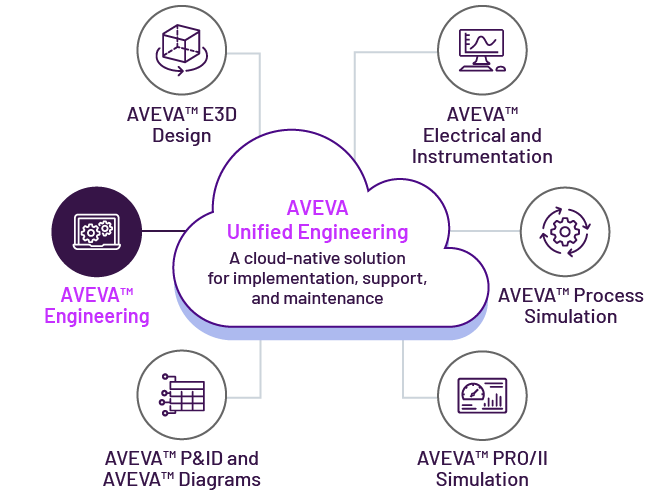

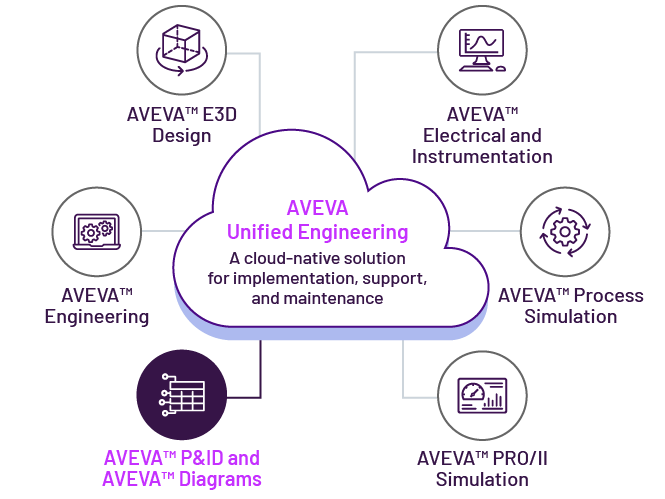

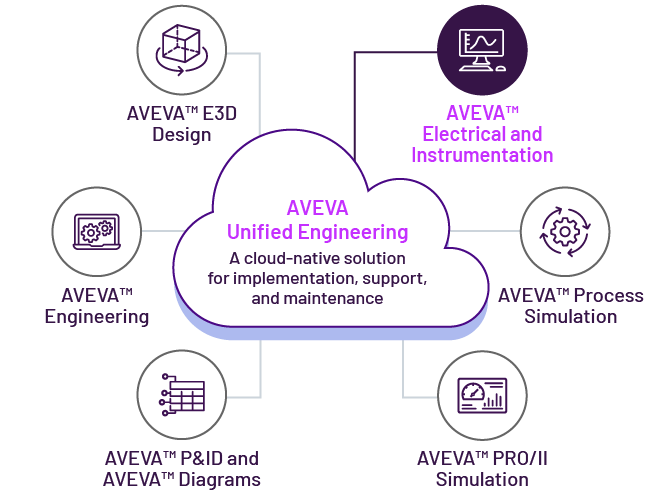

What is AVEVA Unified Engineering?

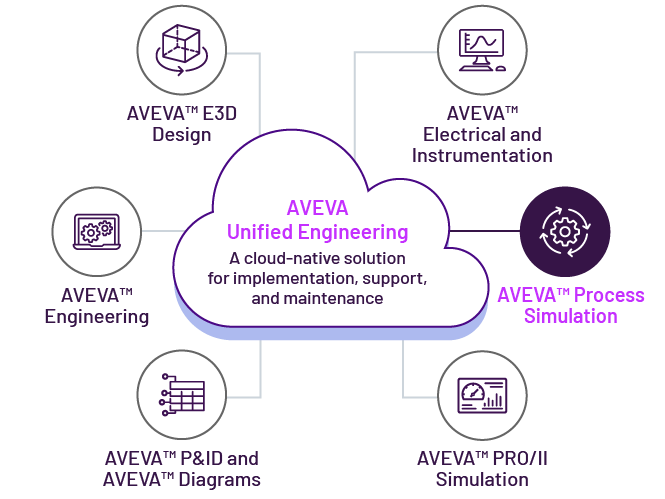

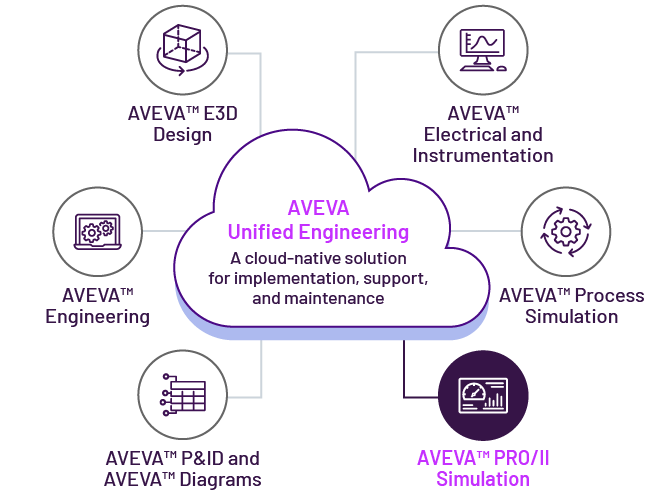

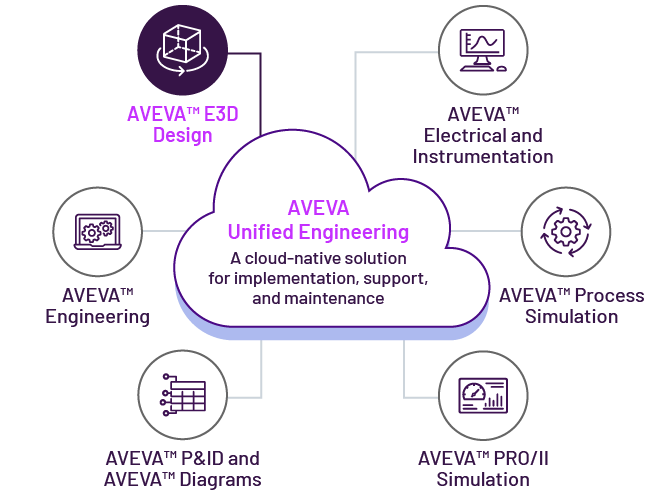

Leveraging SaaS capabilities through our industrial cloud platform, Connect, AVEVA Unified Engineering is a data-centric environment for real-time engineering data. Spans the conceptual design, front-end engineering and design (FEED), and detailed design phases of your project's lifecycle.

AVEVA Unified Engineering features

Wood collaborates with AVEVA to reduce building costs

Wood a global engineering, procurement, and construction company developed a strategy to standardize materials and construction management.

Unified Engineering products

The world's most technologically advanced 3D design solution for the process plant, marine, and power industries.

Connect multi-discipline teams of engineers so they can develop and maintain key engineering items for plant or marine projects.

Build your process diagrams with intelligent, graphical, data-driven applications.

Create instrumentation and electrical drawings, schematics, and data sheets that integrate with ETAP for detailed calculation, and 3D for cable routing.

Use simulation to design sustainable processes, products, and plants more efficiently.

Perform engineering studies to optimize plant performance and improve process design.

Discover Latest News and Resources

Check out the latest news, blogs, events, webinars, and success stories.