InduSoft Web Studio is now AVEVA Edge.

Rashesh Mody welcomes users of AVEVA Edge (formerly InduSoft Web Studio) to AVEVA

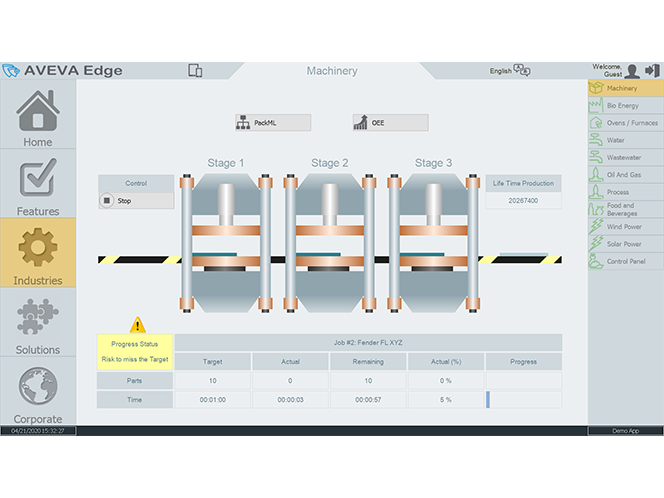

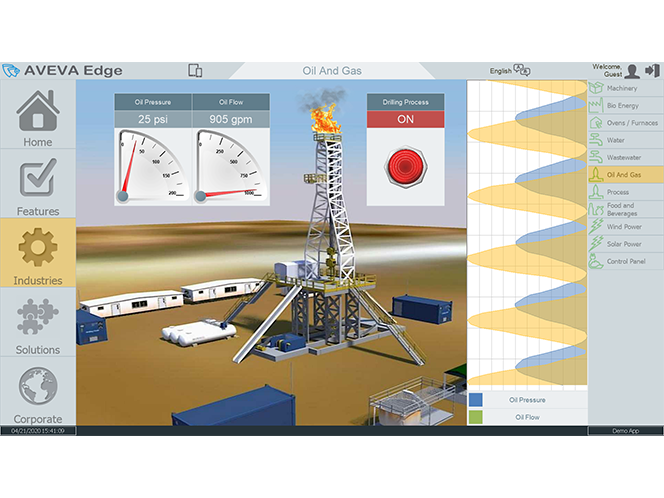

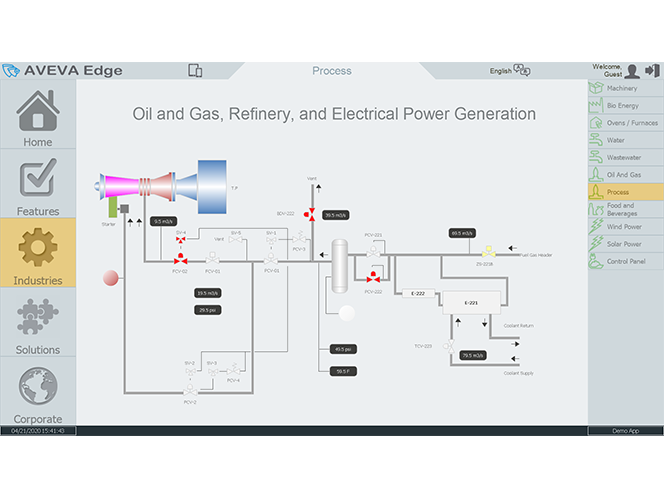

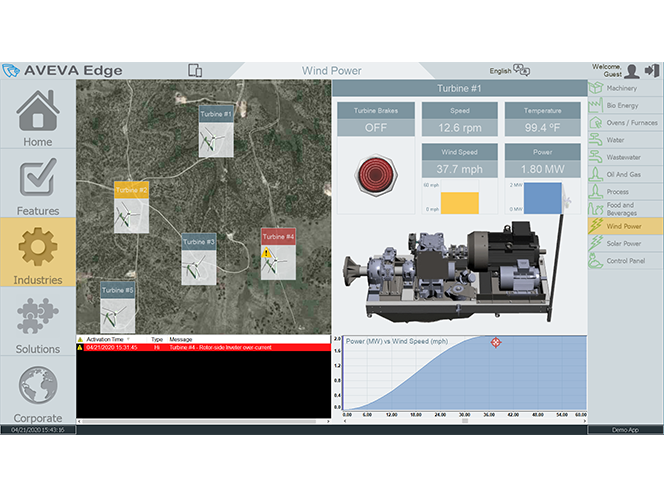

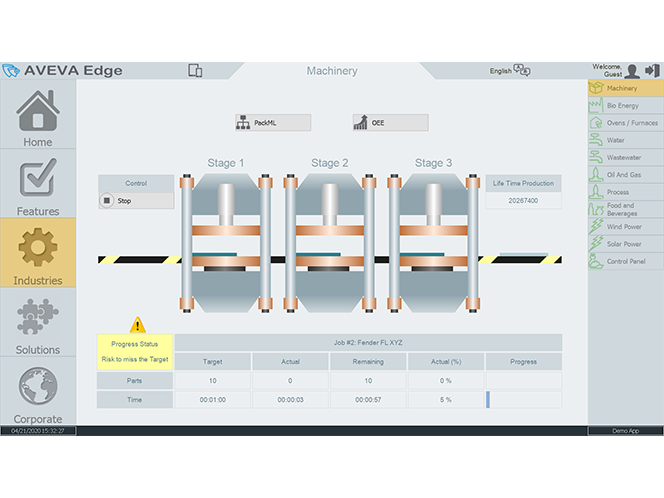

AVEVA Edge Offers Scalable, Flexible HMI/SCADA Solutions

A focus on interoperability, mobility, and portability makes it possible to develop HMI and SCADA software in a single development environment for deployment everywhere.

About AVEVA™ Edge

Enable a line of sight from System Platform SCADA software down to embedded machine-based small systems.

AVEVA Edge Features

Unique software capabilities make it easy and cost effective for you to use AVEVA Edge to build smarter end-to-end automation systems.

90%

Reduction in development times during conversion process

500k+

Licenses deployed worldwide

Client Success Stories

Nita Labeling Equipment

Nita future-proofs its latest labeling machines, to deliver greater productivity by empowering operators with improved cloud-based insights

La Tortilla Factory

AVEVA software streamlines and improves manufacturing processes and controls costs with comprehensive process automation solutions for La Tortilla Factory.

AVEVA Edge License Activation and Management

AVEVA provides simple, flexible licensing options for AVEVA Edge. All main features are supported in every license. Use the links below to activate your AVEVA Edge (and InduSoft Web Studio legacy) licenses for commercial and educational use.

You will receive an email after purchase with a License Certificate containing a description of your license and its unique serial number.

In order to activate your license, you must register for a New AVEVA Web Account. After successfully verifying the information, AVEVA will activate your account within 1-2 business days. Registration is free of charge.

After your account is activated sign into the AVEVA Edge licensing portal and follow the instructions on the page to obtain your license (Activation Code). You will need the serial number from the License Certificate as well as the Hardware Identifier generated by AVEVA Edge installed in your computer/device.

You will receive an email after purchase with a License Certificate containing a description of your license and its unique Activation Key.

After your account is activated, you can sign into the InduSoft Web Studio licensing portal and follow the instructions on the page to obtain your license (Site Key). You will need the serial number from the License Certificate as well as the Site Code generated by InduSoft Web Studio installed in your computer/device.

(Also valid for InduSoft Web Studio Legacy Educational Partners)

After signing an Educational Agreement with AVEVA, you will receive a unique Activation Key for your Educational organization.

Sign in to the AVEVA Edge Educational License for Universities portal and follow the instructions on the page to obtain your license (Activation Code). You will need the Activation Key from the Educational Agreement, as well as the Hardware Identifier (Site Code) generated by AVEVA Edge installed in your computer/device.

(Also valid for InduSoft Web Studio educational licenses)

Sign in to the AVEVA Edge Educational License for Students portal and follow the instructions on the page to obtain your license (Activation Code). You will need the Hardware Identifier (Site Code) generated by AVEVA Edge installed in your computer/device.

Discover the Latest News and Resources

Check out the latest news, blogs, events, webinars, and success stories.