Predict future performance to make better decisions today

Posted: August 04, 2023

Get predictive to make proactive decisions for your chemicals plant

Market demand, pricing fluctuations, and increasing pressure to decarbonize and join the circular economy means chemicals companies are rethinking operations. Now, they must find new ways to reduce waste and emissions, minimize downtime, and improve margins to increase competitive advantage and decrease environmental impact. To get there, every part of the operation—from the plant floor to the enterprise level, processes to people—needs access to the right tools and insights to become more agile than ever.

So how can chemicals companies—particularly plants that have been optimized for years—uncover new ways to overcome current challenges? They must innovate. With the right data, visualization, and models and analytics strategies, chemicals operators can predict future performance to make better decisions today.

Innovation isn’t just a long-term strategy

Innovation isn’t just a long-term strategy. Companies must also take a short-term approach, and the best way is to use digital technology to give every stakeholder clear visibility into existing data, assets, and processes so they can drive continuous improvements every minute of every day.

Chemicals companies with a robust data infrastructure that can give users access to contextualized data are already a step ahead of the competition. With visibility into past and real-time operations, users can model and predict future performance and take active steps to reach profitability and sustainability goals. When chemicals operations build on the right data to generate insights, companies can prioritize digital initiatives and users can make proactive decisions, which ultimately allows plants to become more agile than ever.

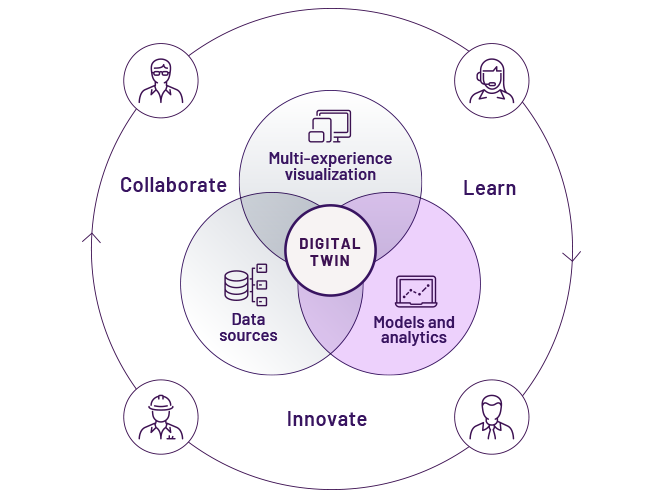

Predicting future plant performance to reach today’s goals requires a three-step approach to digital initiatives:

- Data: The first step is to access operational data from multiple sources and build a digital strategy to ensure improvements. Many AVEVA customers use AVEVA™ PI System™, which acts as a single source of truth for all operational data, giving users access to all data in one single contextualized environment.

- Visualization: Once all data is centralized into one data management infrastructure, users need access to the right tools to visualize data and key performance indicators (KPIs). Today, users across the enterprise can visualize and access data and KPIs from full-screen displays or tablets in the palms of their hands.

- Models and analytics: By using models and analytics, users can take current and past data to predict plant and asset behavior. Using AVEVA™ Predictive Analytics, chemicals operations can gain the right insights and guidance about which actions to take to keep operations stable, profitable, and in line with sustainability goals and overarching business strategies. This can be taken one step further with the adoption of AVEVA™ Process Simulation. Decision-makers gain insight into process variables that cannot be measured to proactively predict reliability issues.

Together, the three digital initiatives lay the foundation for future innovation, including digital twins.

Together, the three digital initiatives lay the foundation for future innovation, including digital twins.

Chemicals companies have access to a variety of digital tools, using different modeling approaches that are fast and easy to implement. From traditional thermodynamic equations to modern machine learning models, when chemicals companies give teams the best tools to develop models and analytics, they can make proactive decisions, reap excellent short-term benefits, and create the right ecosystem to enable a connected, profitable, and sustainable future.

Learn how models and analytics can extend the value of your data.

Related blog posts

Stay in the know: Keep up to date on the latest happenings around the industry.