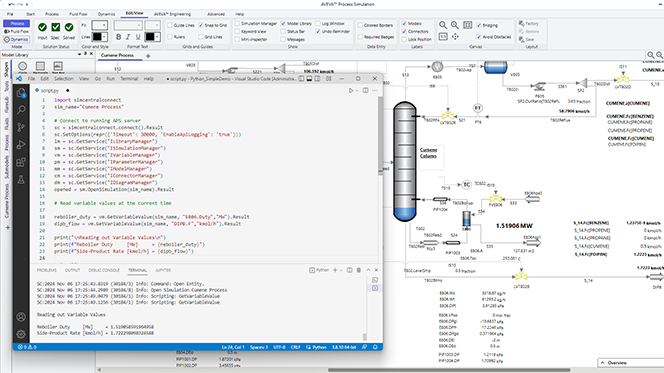

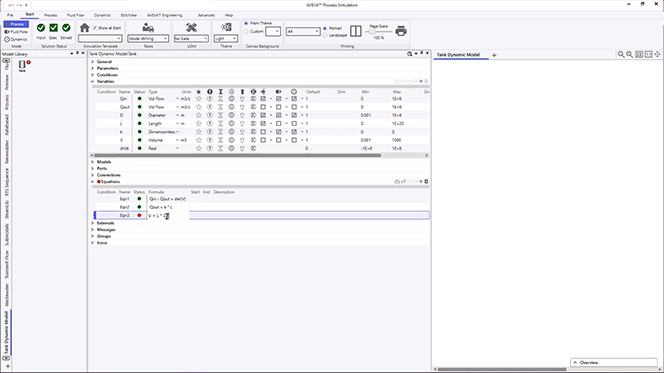

Covestro cuts inefficiencies in process design, engineering, and simulation

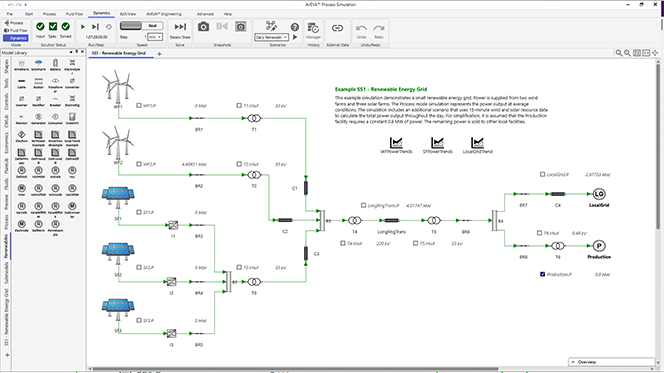

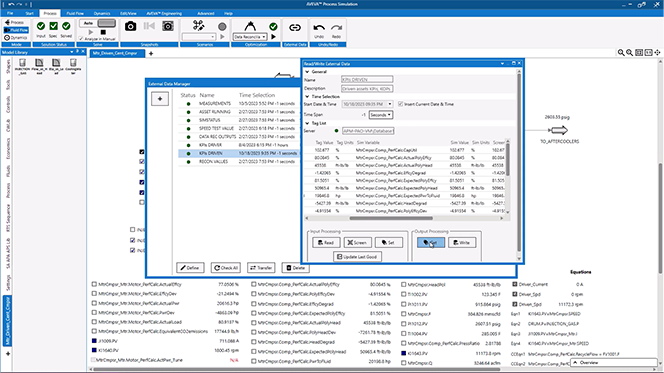

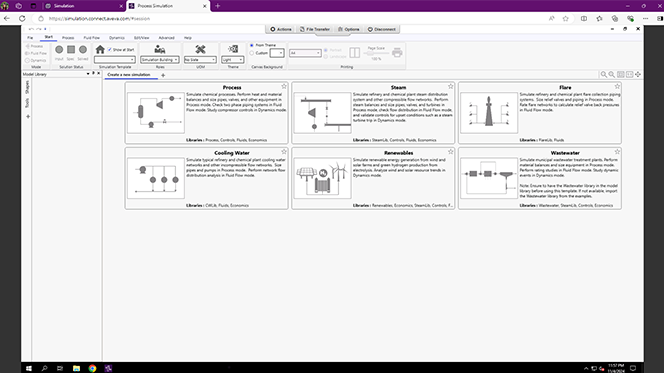

Covestro digitally transformed its production processes with a digital twin of process behavior using a single, easy-to-use platform. Engineers across disciplines work on the same processes using the same tool, spurring collaboration and innovation.