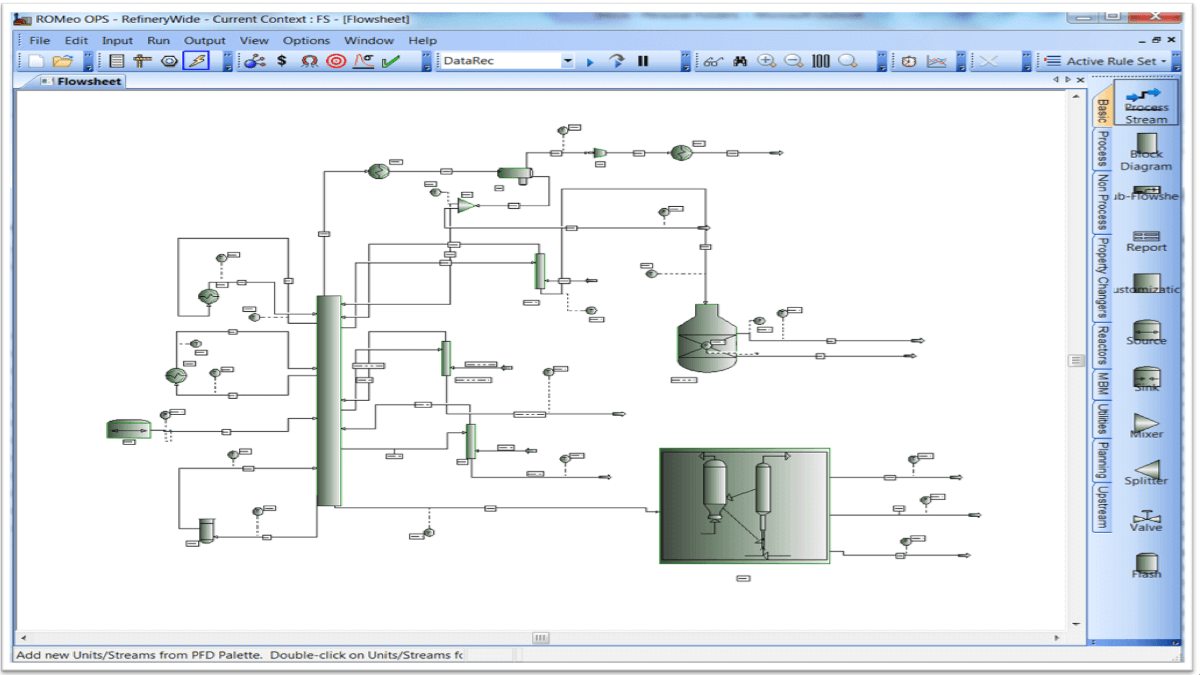

The Digital Twin of Reactor Units

- Open-equation based rigorous kinetic models with mass and energy balance

- They are updated automatically through ROMeo’s external data

Optimizing Reactor Units

Rigorous reactor models allow optimizing the operation of the reactor units and maximize the benefit of ROMeo’s nonlinear optimization.

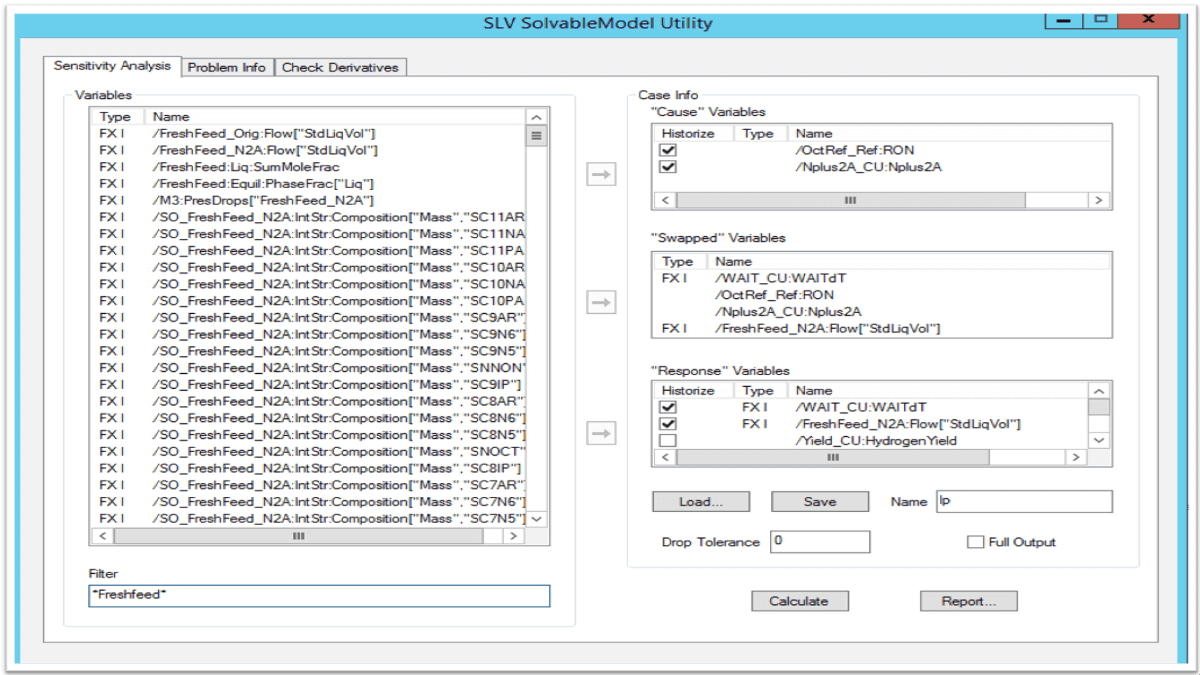

Greater Accuracy in Linear Programming (LP) Updates

Generate more accurate LP vectors for the reactor units from the Jacobian matrix (first order derivatives) of the reactor model rather than through tedious and time-consuming perturbation tests.

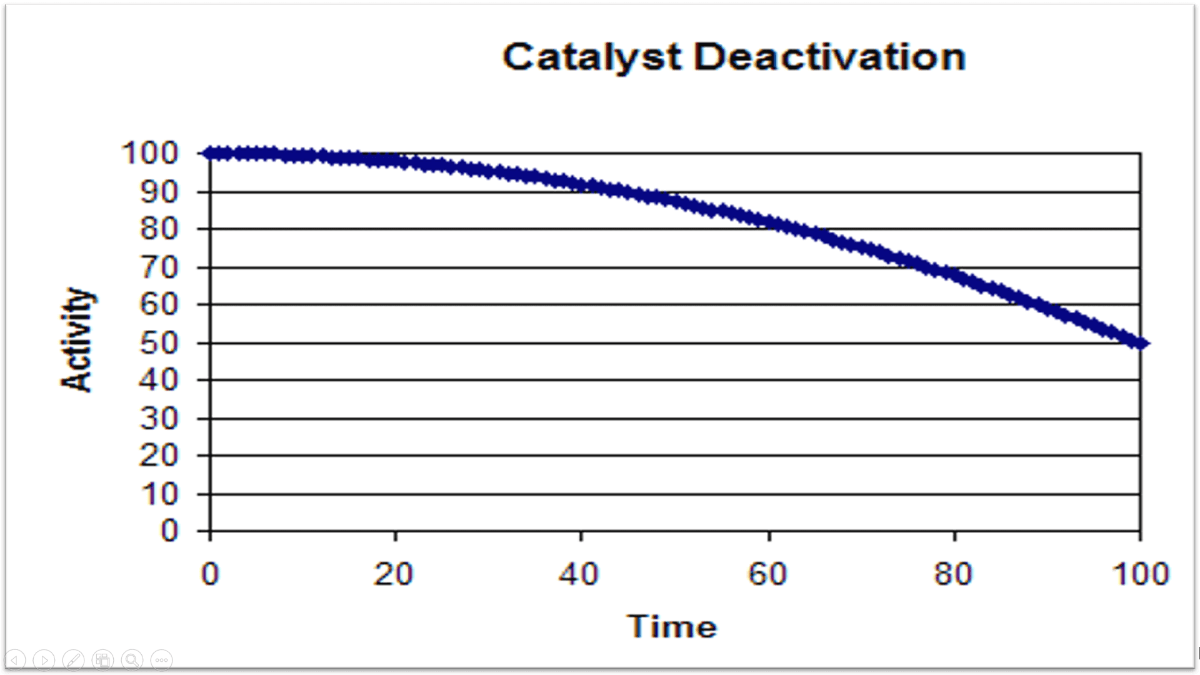

Catalyst Performance Monitoring

- Monitor catalyst activity and selectivity real-time

- Troubleshoot abnormal catalyst deactivation

- Predict catalyst run-time

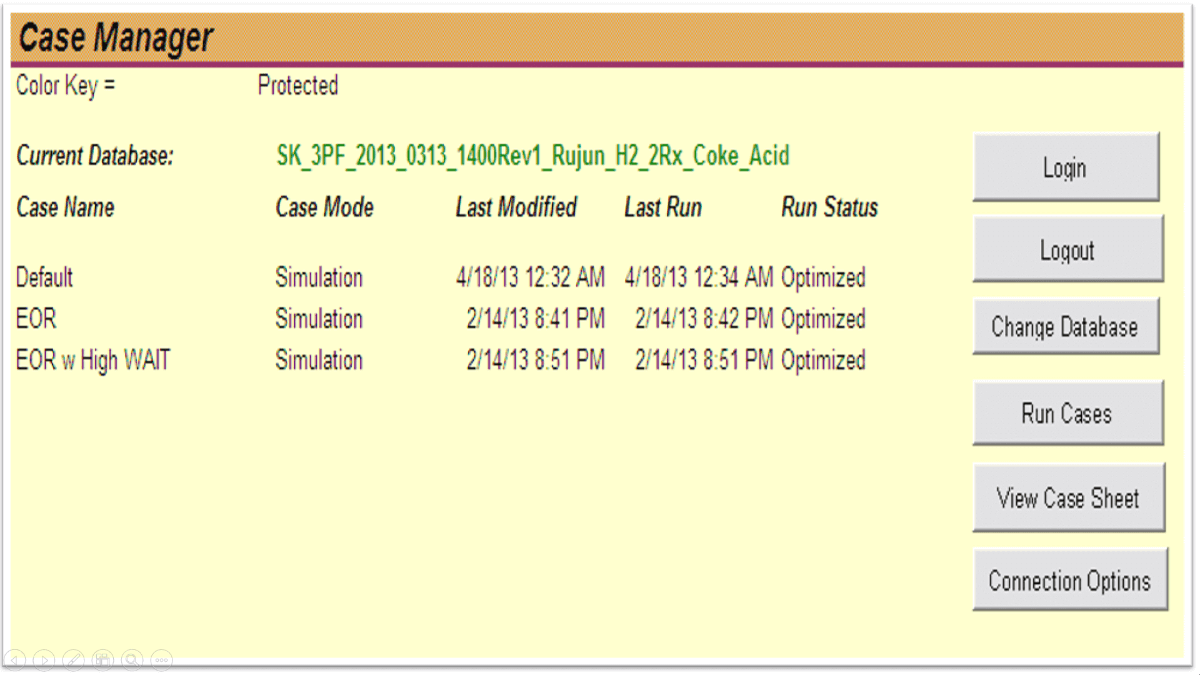

Offline Case Study

Use reactor models to do offline simulation, “what-if” case studies, feedstock selection, or offline optimization studies.

Specifications

Type

Software

Optimized Scenario

Rigorous kinetic models with mass and heat balance ideal for refineries, ammonia and coal gasification industries.

Available on

PC

Languages

English

AVEVA Group Limited

AVEVA creates industrial software that inspires people to shape the future. We believe industry advancement should enhance the human experience.

Related Products

AVEVA Process Optimization: Material Balance Module

Originated from rigorous modeling technology designed for process engineers to perform statistically-based data reconciliation of meters in a single processing unit or around a group of processing units

AVEVA Process Optimization

Formerly Known As ROMeo Process Optimization

Boost Profitability with Real-Time Process Optimization by maximizing your operating profit and improving plant performance with AVEVA Process Optimization.

AVEVA Off-sites Management

Formerly Known As Refinery Off-Sites

AVEVA Offsites Management provides accurate, reliable, and accessible inventory and movement information, movement automation and more!

Advanced Process Control | AVEVA APC

Formerly Known As Advanced Process Control

Improve your oil and gas operations with AVEVA APC. Our model predictive control technology extracts maximum value from your processes.

AVEVA Unified Supply Chain

Formerly Known As Spiral Unified Supply Chain Management

Optimize YOUR Supply Chain with the ultimate cloud-enabled oil and gas supply chain management software from AVEVA. Faster, smarter, and tailored for O&G.

AVEVA Production Accounting | Yield Accounting

Formerly Known As ErrorSolver

Transform your oil and gas production accounting. Streamline your operations and increase productivity with AVEVA's powerful production accounting software.