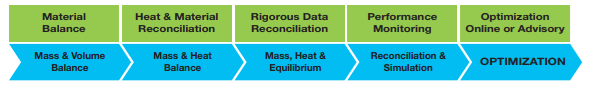

What to Expect with Material Balance Module?

- Daily consistent and accurate mass and volume balances

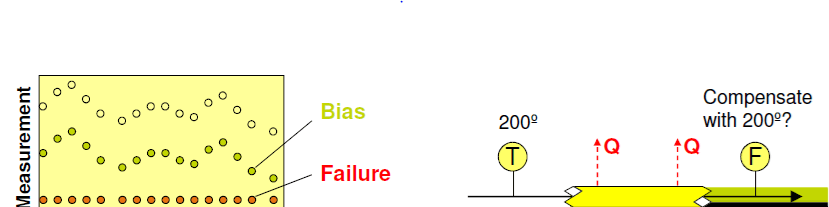

- Detect meters in gross error rapidly: No need to wait for the end-of-month yield accounting problems to identify bad meters

- Supports yield accounting to close the monthly balances

- Generates values for unmeasured flows or unreliable meters

- Ensures that instrument staff works only on broken meters

Reconcile Material Balances

- Identify & correct faulty meters, aid in loss detection for the process area that is modeled

- Produce reconciled (adjusted) stream rates

- Reconciles stream flow rates, where the focus of measurement is on rate data: stream flow rates (not cumulative quantities)

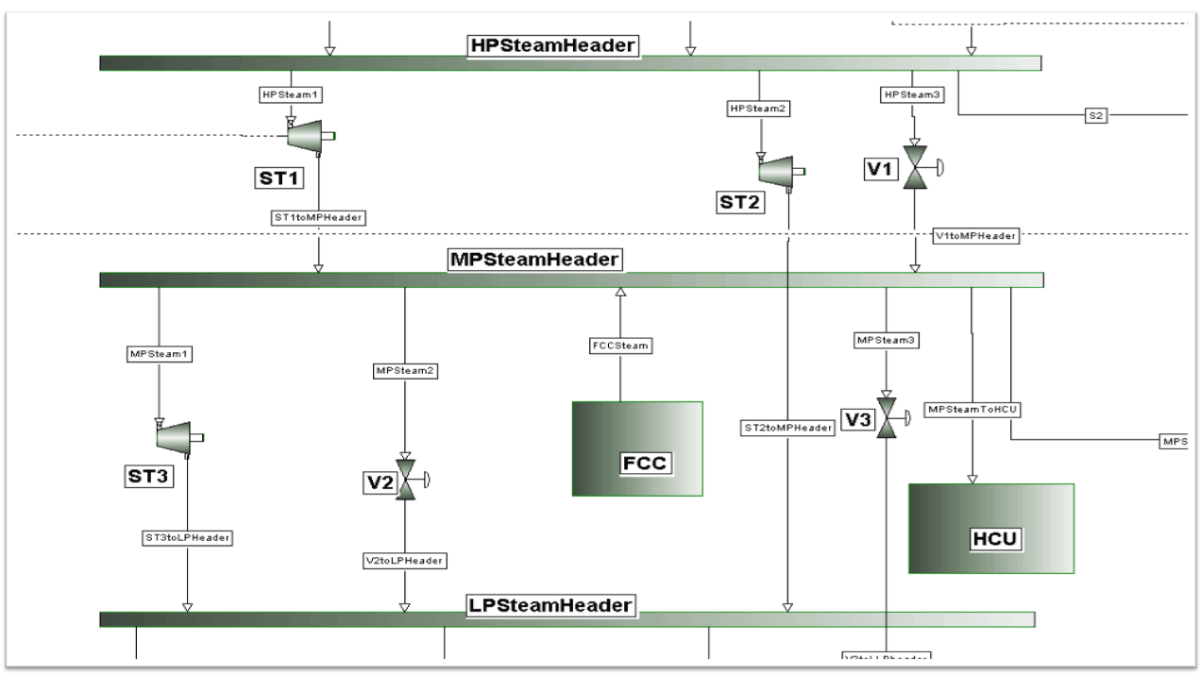

Flexible Flowsheet and Modeling

- Rigorous model configuration and maintenance

- Data interfacing and integration

- User customization

- Sequencing and scheduling manager

- Thermodynamics library

Gross Errors Detected

- Measurement Screening

- Measurement Testing

- Constraint Testing

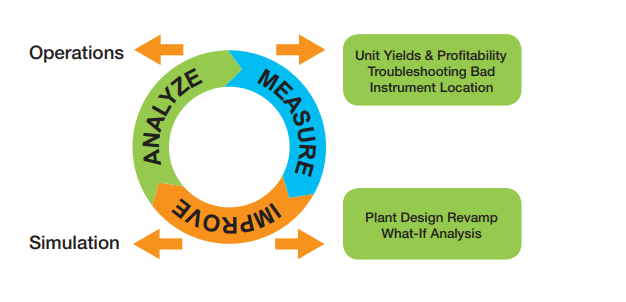

Key Applications

- Producing daily material balances around major units in a process to identify bad meters

- Operations and turn-around decision support based on accurate, consistent data

- Accurate monitoring and managing of throughput as part of a loss prevention program

- Obtaining consistent data for LP updates and yield accounting

- Accident and shutdown avoidance by identifying gross errors in instrumentation before they trigger any alarms

- Efficiently setting maintenance schedules for flow instrumentation

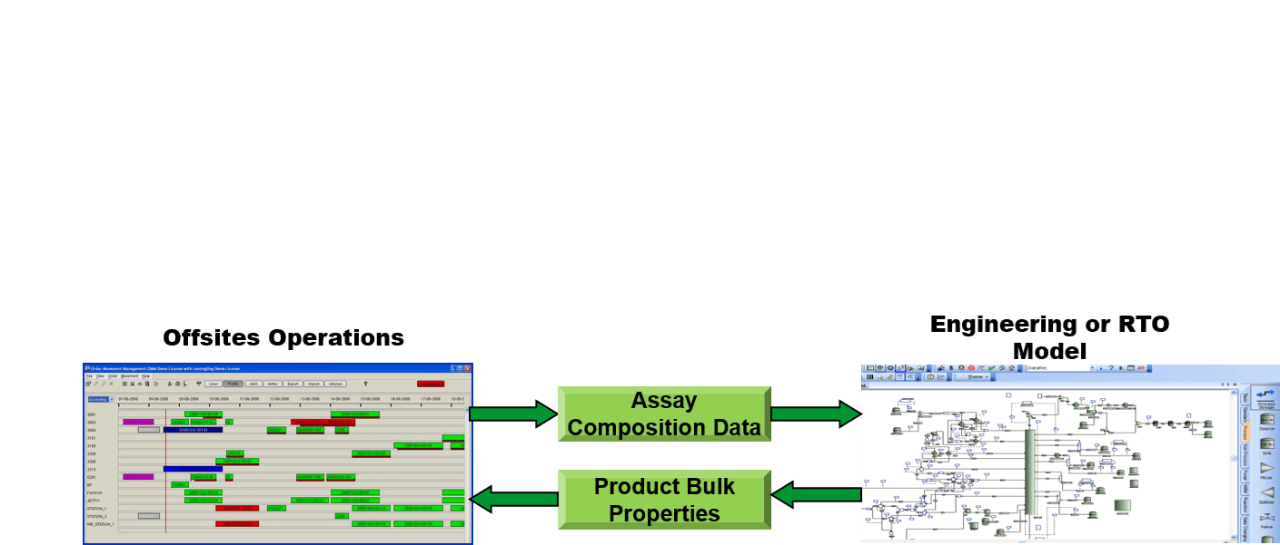

Integration with Off-sites

- Improved Crude Feed composition improves Material Balance results

- Optimized Product property data improves Off-sites product blending output

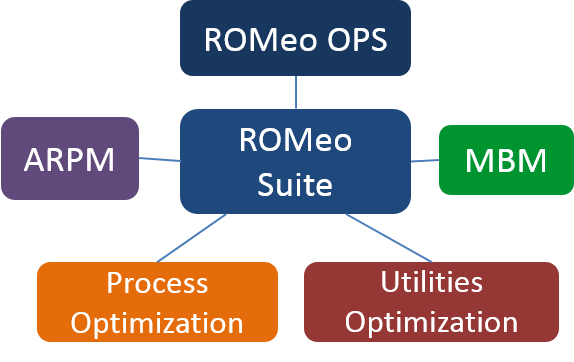

Extensible Functionality

- Rigorous heat and material balance

- Online performance monitoring

- Operations decision support modeling through closed-loop optimization

Specifications

Type

Software

Optimized Scenario

Designed for process engineers to reconcile stream flow rate data in a processing facility.

Available on

PC

Languages

English

AVEVA Group Limited

AVEVA creates industrial software that inspires people to shape the future. We believe industry advancement should enhance the human experience.

Related Products

AVEVA Process Optimization

Formerly Known As ROMeo Process Optimization

Boost Profitability with Real-Time Process Optimization by maximizing your operating profit and improving plant performance with AVEVA Process Optimization.

AVEVA Process Optimization: Reactor Models

Create rigorous kinetic models - the digital twin for refinery conversion units. Helps in simulation, optimization, performance monitoring and linear programming updates to maximize reactor performance.

AVEVA Off-sites Management

Formerly Known As Refinery Off-Sites

AVEVA Offsites Management provides accurate, reliable, and accessible inventory and movement information, movement automation and more!

AVEVA PRO/II Simulation – The Trusted Steady-State Process Simulator

Formerly Known As PRO/II Process Engineering

A simulator that optimizes plant performance improves your process design and operational analysis by performing engineering studies.

AVEVA Process Simulation

Formerly Known As SimCentral Simulation Platform

Design sustainable processes, products, and plants at the speed the market demands. AVEVA Process Simulation moves beyond linear, wasteful workflows to enable a circular, sustainable world.

AVEVA Production Accounting | Yield Accounting

Formerly Known As ErrorSolver

Transform your oil and gas production accounting. Streamline your operations and increase productivity with AVEVA's powerful production accounting software.