Manufacturing a data-driven future through shared operations data visualization

Posted: March 21, 2024

Avebe, the international starch manufacturer, shared its journey to build a data-driven organization to increase overall productivity and quality. Avebe believed that “accessibility of data is paramount for informed decision-making at all levels of business.” The manufacturer was teeming with data, but had yet to transform it effectively to make it meaningful for its staff at production sites." To tackle this problem head-on, Avebe focused on enabling its people with operational intelligence. Avebe used AVEVA™ PI System™, the market-leading operations data management solution, as the main platform to build this operational intelligence.

Tear down the wall between departments by sharing operations data visualization

Avebe's production framework required buffer silos to be filled as quickly as possible. The production staff followed orders, yet they were unaware that a packaging line, located in a different building, had experienced a breakdown and was at a standstill. Because the downstream packaging process had halted, the buffer silo reached 100% capacity and ran the risk of overfilling. Overfilled silos disrupt operations, damage equipment, and pose serious safety risks. Cleaning up, repairing damages, and dealing with potential legal fallout can all drain time and money.

Acknowledging the need for both departments to have visibility into each other’s statuses, Avebe turned to its operational intelligence strategy. A key part of the strategy included not only the visualization of operations data, but also sharing those visualizations. This aspect of the strategy ended up making it into the best practices guide for the company. To enable display sharing, Avebe used AVEVA™ PI Vision™, the flagship visualization tool for AVEVA PI System.

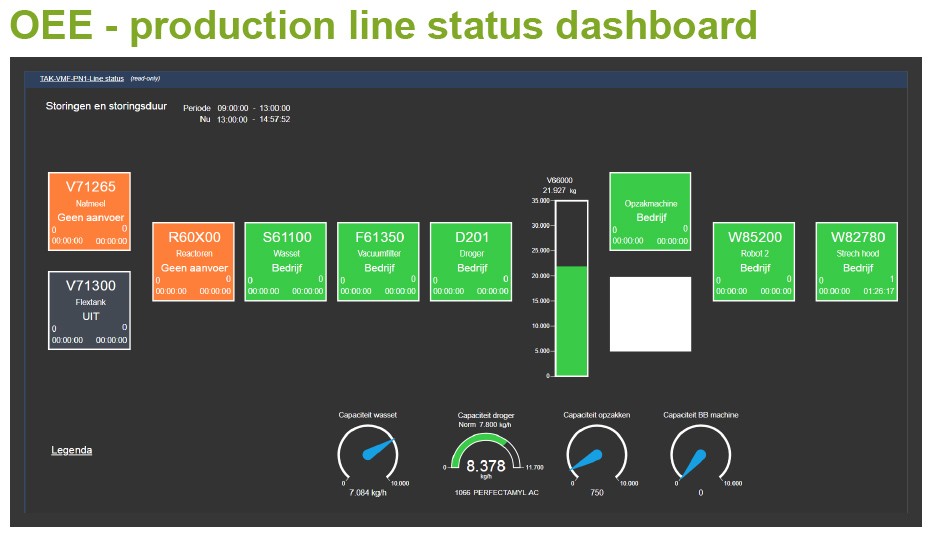

AVEVA PI Vision makes securely sharing displays with colleagues as easy as sharing a link to a webpage. All that’s required is a URL to the display, and easily configured read or write permissions. Avebe built a unit status dashboard in AVEVA PI Vision that’s shared among the departments. Now, staff in the production area can see when the packaging line has a breakdown. They can communicate with the packaging staff and determine if they need to reduce the production capacity or just produce as planned.

Figure 1: This AVEVA PI Vision display shared between Avebe’s production and packaging departments features indicators for process flow, buffer silo capacity and real-time alerts for equipment breakdowns, enabling immediate inter-departmental communication and operational adjustments to prevent production delays.

Enhance supply chain efficiency by sharing real-time operations dashboards

Avebe works with external transporters. The manufacturer wanted to securely share real-time information about the status of its silos with the transporters so that they could adjust their schedules and logistics accordingly. AVEVA PI Vision offers Windows-based and modern claims-based authentication options, enabling flexible security and architectural options for different use cases. Avebe used an Azure proxy with AVEVA PI Vision to securely provide the transporters access.

Figure 2: This image shows Avebe’s real-time silo dashboard in use at one of its external transporters.

Increase collaboration with shared operations intelligence and visualization

Avebe shared several other operations data visualization use cases, including an energy monitoring system display in AVEVA PI Vision for driving continuous sustainability and energy efficiency optimization. This allows staff to build their own displays like those at Avebe and develop new insights to share with colleagues. In this way, innovation flourishes in an industrial organization. At an organization like Avebe, where most employees were set to retire in the next five to ten years, this kind of sharing can be critical for a collaborative transition to a younger workforce.

Since implementing AVEVA PI System, Avebe said it had around 200 internal users with over 65,000 data tags in use between them. The barriers between departments were pretty much gone. Avebe attributed the increased collaboration to sharing, saying staff “go to each other easier and share the knowledge, share the displays.” Not only that, because staff more actively engage with their data, Avebe has observed improvements in data quality.

If you’d like to learn more about how AVEVA PI Vision securely provides real-time operations data visualization and empowers data users throughout the industrial world, check out our on-demand webinar, “Visualizing operations across the enterprise: How self-service tools accelerate real-time insight.”

Related blog posts

Stay in the know: Keep up to date on the latest happenings around the industry.